عنا

مرحبا هل يمكنني مساعدتك؟

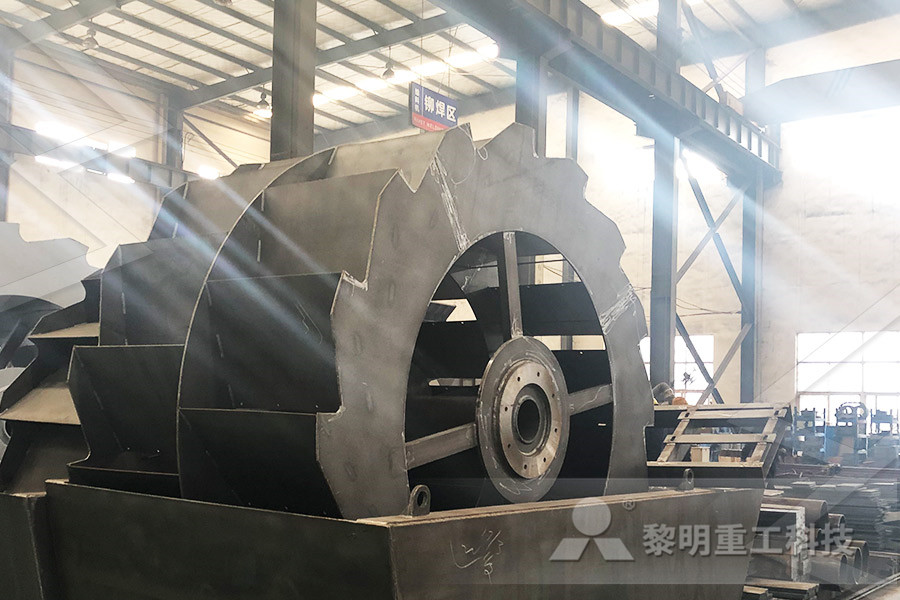

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

foundation ball mill german grinding

(PDF) DYNAMIC DESIGN FOR GRINDING MILL FOUNDATIONS

A practical case of ball mill foundation is examined herein The diameter of mill is 80 m with length of 131 m, operating at 12 rpm The height of mill shaft is 181 m above ground The weight ofA ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axis of Ball mill WikipediaBall mills are allrounders and together with their broad range of accessories they allow dry, wet, and even cryogenic grinding in one instrument Especially for elastic samples (eg plastics) and instable samples such as materials which contain volatile components, cryogenic grinding ensures a homogeneous final sample which provides the best recovery rates, even for subsequent quantitative Milling and Grinding :: AntonPaar

foundation ball mill german grinding

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsSepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application No auxiliary drive is required to perform maintenance, Tire Drive Grinding Mills Mineral Processing EquipmentCeramic ball mill is mainly used in material mixing grinding henan fote heavy machinery co ltd has two kinds of grinding ceramic ball mill one is dry grinding ceramic ball mill and another is wet grinding ceramic ball mill the machine can use different liner types according to Fritsch Sample Preparation And Particle Sizing Milling Fritsch one step ahead fritsch is an internationally Ball Mill Grinding Machine Germanyball Mill

Three Methods To Improve The Production Of Ball Mill

First, assign a former mill impact crusher, so the ore crusher will first be broken into particles, reducing the load on the ball; Second, the improved grinding system; Third, an efficient separation is provided, and ultimately the powder was sieved Three optimize mill production methods mentioned here, crushing is a prerequisite; separation is guaranteed; grinding is the foundationstirred media mills and highpressure grinding rolls, ball mills still retain a significant part of their importance in grinding, being widely used from minerals and cement, to chemicals and ceramics The operation of a ball mill is a capital and energyintensive process, so that even marginal improvements in their efficiency result in immenseA Review of Advanced Ball Mill ModellingMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

grinding jar German translation – Linguee

Grinding method in which a) a proportion of the material which is comminuted in a ring mill (1) and discharged over the edge of the grinding track (3a) of this ring mill is carried upwards by an air stream which is delivered from below via an air ring (6) which surrounds the grinding track, b) whilst the remaining proportion of the material discharged over the edge of the grinding track falls Ball mills are the allrounders covering a very broad application spectrum and ensuring homogenous samples of sufficient fineness for your special analytical task with a minimum of preparation effort Dry, wet, instable samples – all with one instrument Ball mills are allrounders and together with their broad range of accessories they allow dry, wet, and even cryogenic grinding in one Milling and Grinding :: AntonPaarSepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application No auxiliary drive is required to perform Tire Drive Grinding Mills Mineral Processing Equipment

A Review of Advanced Ball Mill Modelling

stirred media mills and highpressure grinding rolls, ball mills still retain a significant part of their importance in grinding, being widely used from minerals and cement, to chemicals and ceramics The operation of a ball mill is a capital and energyintensive process, so that even marginal improvements in their efficiency result in immenseCeramic ball mill is mainly used in material mixing grinding henan fote heavy machinery co ltd has two kinds of grinding ceramic ball mill one is dry grinding ceramic ball mill and another is wet grinding ceramic ball mill the machine can use different liner types according to Fritsch Sample Preparation And Particle Sizing Milling Fritsch one step ahead fritsch is an internationally Ball Mill Grinding Machine Germanyball MillFirst, assign a former mill impact crusher, so the ore crusher will first be broken into particles, reducing the load on the ball; Second, the improved grinding system; Third, an efficient separation is provided, and ultimately the powder was sieved Three optimize mill production methods mentioned here, crushing is a prerequisite; separation is guaranteed; grinding is the foundationThree Methods To Improve The Production Of Ball Mill

BUILDING A SOLID FOUNDATION FOR YOUR MILL

The grinding mill is at the heart of a mining operation, but a poorly designed or constructed foundation will not only affect grinding mill performance but potentially render the mill out of action – thereby costing millions of dollars in lost production The following advice will help ensure the foundation is right before you install a new mill Foundation load specification It is the INTRODUCTION It is well known that the dry grinding of cement and coal in tumbling ball mills becomes inefficient as the amount of fine powder in the mill becomes large Hukki [I] has shown that the increase of surface area of cement (measured with the BET technique) per unit of energy input decreases as the material becomes very fine and, eventually, further grinding produces virtually no An analysis of fine dry grinding in ball mills ScienceDirectMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

TECHNICAL NOTES 8 GRINDING R P King Mineral Tech

Figure 82 Media motion in the tumbling mill 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles Paste plant foundation underway June 2019 Bomboiza substation SAG and ball mills inside the grinding building Primary crusher and ore conveyor under construction Regrind mill Bolting and meshing in K'isa level 1195 development on this level to the South Vent Raise is 74 days ahead of plan Grinding building is nearing completion May 2019 Underground advance ahead of target Aerial Photo Gallery Lundin Gold IncPlanetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and Planetary Ball Mill PM 100 RETSCH highest fineness

Outotec® MH Series Grinding Mills Outotec

Outotec® MH Series Grinding Mills offer a cost effective, and easy to operate and maintain grinding solution across the mill lifecycle The MH Series includes a range of SAG, ball, and rod mills in standardized sizes with a capacity of up to 31 MW installed power, and is based on over 100 years of experience with grinding technologies Proven and robust technology based on Outotec standard Sepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application No auxiliary drive is required to perform Tire Drive Grinding Mills Mineral Processing EquipmentCeramic ball mill is mainly used in material mixing grinding henan fote heavy machinery co ltd has two kinds of grinding ceramic ball mill one is dry grinding ceramic ball mill and another is wet grinding ceramic ball mill the machine can use different liner types according to Fritsch Sample Preparation And Particle Sizing Milling Fritsch one step ahead fritsch is an internationally Ball Mill Grinding Machine Germanyball Mill

BUILDING A SOLID FOUNDATION FOR YOUR MILL

The grinding mill is at the heart of a mining operation, but a poorly designed or constructed foundation will not only affect grinding mill performance but potentially render the mill out of action – thereby costing millions of dollars in lost production The following advice will help ensure the foundation is right before you install a new mill Foundation load specification It is the INTRODUCTION It is well known that the dry grinding of cement and coal in tumbling ball mills becomes inefficient as the amount of fine powder in the mill becomes large Hukki [I] has shown that the increase of surface area of cement (measured with the BET technique) per unit of energy input decreases as the material becomes very fine and, eventually, further grinding produces virtually no An analysis of fine dry grinding in ball mills ScienceDirectsolutions include ball mill strategies that achieve the target grind size while maximizing throughput, or when the circuit is SAG mill limited, achieve the finest grind size possible, thus increasing mineral liberation and recovery GrindingExpert™ has been shown to typically increase throughput by 36% GrindingExpert™ More Tonnage Better Grinding GrindingExpert™ is a turnkey grinding GrindingExpert™ WordPress

TECHNICAL NOTES 8 GRINDING R P King Mineral Tech

Figure 82 Media motion in the tumbling mill 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles german grinding mill indian bmd Homepage gtnew machinegtgerman grinding mill indian bmd Other Case rubber conveyor belt splicing company in the middle east bauxite mining in suriname site, Get Quote Grinding Mills AG Printing Thickners India LLP Partner, Ganesh Grinding Mills Pvt,German Estrada 2015 9 18 The 4 opportunities yourGerman Bmd Grinding Mill India nemovitostizahraniciczPaste plant foundation underway June 2019 Bomboiza substation SAG and ball mills inside the grinding building Primary crusher and ore conveyor under construction Regrind mill Bolting and meshing in K'isa level 1195 development on this level to the South Vent Raise is 74 days ahead of plan Grinding building is nearing completion May 2019 Underground advance ahead of target Aerial Photo Gallery Lundin Gold Inc