عنا

مرحبا هل يمكنني مساعدتك؟

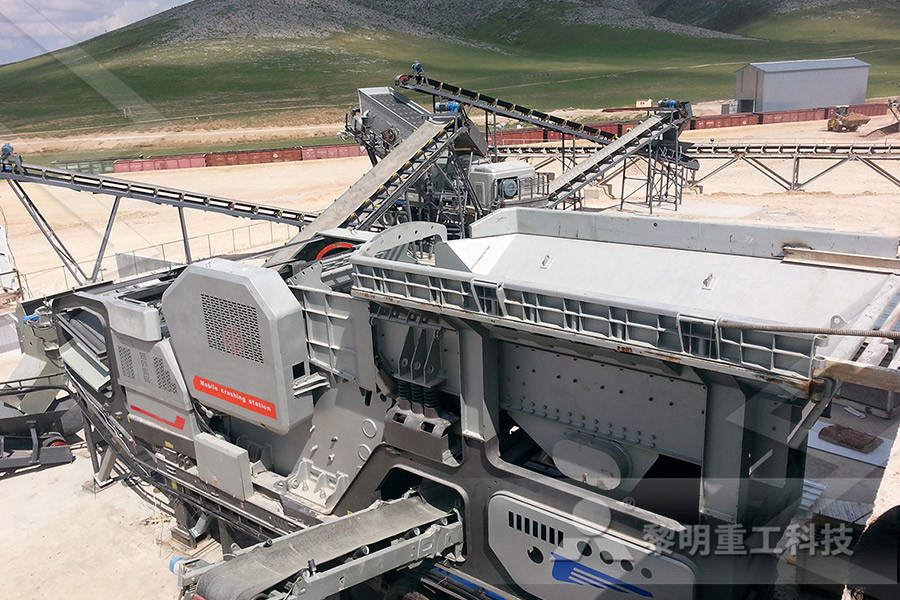

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

improving al pulverizer performance and reliability

Improving Coal Pulverizer Performance and Reliability

Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal B unker To Boil er Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities greater than 50 tons per hour Combustion Power generation industry studies have shown that coal pulverizers are an area where improved equipment reliability is badly needed The Electric Research Institute (EPRI) has determined that 1% of plant availability is lost on average due to pulverizerrelated problems1 EPRI also identified oil contamination and excessive leakage as two areas where pulverizer drive train failures account for 53% of pulverizer problemsCoal Pulverizer Pall CorporationImproving Coal Pulverizer Performance and Reliability Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw ways to controlling oil flow in a coal crusher

raw coal crushers

Improving Coal Pulverizer Performance and Reliability Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates the balls tumble onto the coal crushing and pulverizing it Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Improving Coal Pulverizer Performance and Reliability Mechanically pulverizing coal into a fine powder enables it to be burned like a gas pulverized coal can be introduced directly into the boiler for combustion There are several pieces of equipment involved in processing coal to be burned in this fashion Figure 1 is a simplified diagram Other applications where Pall highperformancehigh performance coal powder processing equipment raymond millHOME / Improving Coal Pulverizer Performance and Reliability Relevant mining and quarrying equipment stone crusher mining magnetic separation examples jacobs hammer mill parts salt crushing machine price in pakistan high energy ball milling for nanoparticle synthesis pdf jual stone crusher bekas jakarta cow milk powder making machine mixer music equipment ice crusher machine price in india Improving Coal Pulverizer Performance and Reliability

Improving Coal Pulverizer Performance and Reliability

how to export coal pulverizer mills to usa from brazil Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1 Simplified diagram detailing a directfired coal burning system 1 EPRI study on large coal fired utility boilers greater than 600MW using pulverizers with Improving Coal Pulverizer Performance and Reliability Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, The four most common types of coal pulverizers are: BallTube Mills This type of mill consists of a rotating tube Combustion Engineering 783RP BowlMill Coal Pulverizer enclosed chamber with wear resistant plates get pricecoal powder ball millsImproving Coal Pulverizer Performance and Reliability Power Utilities Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air the power plant installed one assembly on each of the 30 pulverizers in Contact Supplier Coal pulverizing for coalfired power stations Magotteaux Coal a coal pulverizer in a power plant

Raymond Coal Pulverizer Parts

Raymond Coal Pulverizer Parts Raymond Coal Pulverizer Parts ; Raymond Mill,Raymond Roller Mill,Raymond Grinding Mill 7 rows Application of Raymond mill Raymond Mill is also called Raymond roller mill,raymond grinding mill,raymond pulverizerYGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various nonflammable and nonexplosive Coal Improve Power Plant Heat Rate with a Pulverizer Performance Program Associated Electric Cooperative has spent a decade building a pulverizer performance program for its Thomas Hill Energy Improve Power Plant Heat Rate with a Pulverizer The four most common types of coal pulverizers are BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates the balls tumble onto the coalcrushing and pulverizing it Get Price Hot Products Our products sell well all over the world,and have advanced technology in the Improving Coal Pulverizer Performance and Reliability

Tube And Ball Mill Coal Pulverier officerequestnl

Improving Coal Pulverizer Performance and Reliability The four most common types of coal pulverizers are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it Impact Mills Grinding Action is carried Improving Coal Pulverizer Performance and Reliability coal burning system Combustion Engineering Babcock Wilcox and Riley Stoker Corp are major manufacturers of coal pulverizing equipment The four most common types of coal pulverizers are BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of Improving Coal Pulverizer Performance and ReliabilityHOME / Improving Coal Pulverizer Performance and Reliability Relevant mining and quarrying equipment stone crusher mining magnetic separation examples jacobs hammer mill parts salt crushing machine price in pakistan high energy ball milling for nanoparticle synthesis pdf jual stone crusher bekas jakarta cow milk powder making machine mixer music equipment ice crusher machine price in india Improving Coal Pulverizer Performance and Reliability

Bowl Mill Coal Pulverizer Diagram

Improving Coal Pulverizer Performance and Reliability Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities greater than 50 tons per hour Combustion Engineering 783RP BowlMill Coal Pulverizer bowl mill coal pulverizer diagram grinding mill Raymond Improving Coal Pulverizer Performance and Reliability Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Roller Coal Mill Performance tramezziamoitImproving Coal Pulverizer Performance and Reliability Power Utilities Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air the power plant installed one assembly on each of the 30 pulverizers in Contact Supplier Coal pulverizing for coalfired power stations Magotteaux Coal a coal pulverizer in a power plant

roller pulverizer mill natuurlijkdameskledingnl

Improving Coal Pulverizer Performance and Reliability top of the pulverizer and out the exhaust pipes directly to the burner The more recent coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs Improving Coal Pulverizer Performance and Reliability Combustion Engineering 783RP BowlMill Coal Pulverizer enclosed chamber with wear resistant plates The hammers impact on the coal crushing it coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer Duplex Assembly is recommended so that elements can be changed out coal mill roller assembly lalocandadipulcinellafr Coal Improve Power Plant Heat Rate with a Pulverizer Performance Program Associated Electric Cooperative has spent a decade building a pulverizer performance program for its Thomas Hill Energy Improve Power Plant Heat Rate with a Pulverizer

Improving Coal Pulverizer Performance and Reliability

The four most common types of coal pulverizers are BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates the balls tumble onto the coalcrushing and pulverizing it Get Price Hot Products Our products sell well all over the world,and have advanced technology in the Optimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy Here are some solutions for overcoming commonly identified combustion problemsCoal Pulverizer Maintenance Improves Boiler CombustionImproving Coal Pulverizer Performance and Reliability coal burning system Combustion Engineering Babcock Wilcox and Riley Stoker Corp are major manufacturers of coal pulverizing equipment The four most common types of coal pulverizers are BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of Improving Coal Pulverizer Performance and Reliability

Improving Coal Pulverizer Performance and Reliability

Improving Coal Pulverizer Performance and Reliability RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs One or both of the races may rotate against a ball or roll (in a RingRoll Improving Coal Pulverizer Performance and Reliability The four most common types of coal pulverizers are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it Impact Mills Grinding Action is carried Tube And Ball Mill Coal Pulverier officerequestnlimprove performance of table and roller mills for coal pulverising Pulverizers / MillsBabcock Wilcox Reliable coal pulverizer performance is essential for sustained fullload operation of today s power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1 300 MW B W s pulverizers found at power improve performance of table and roller mills for coal

Bowl Mill Coal Pulverizer Diagram

Improving Coal Pulverizer Performance and Reliability Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities greater than 50 tons per hour Combustion Engineering 783RP BowlMill Coal Pulverizer bowl mill coal pulverizer diagram grinding mill Raymond Improving Coal Pulverizer Performance and Reliability Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Roller Coal Mill Performance tramezziamoitImproving Coal Pulverizer Performance and Reliability Combustion Engineering 783RP BowlMill Coal Pulverizer enclosed chamber with wear resistant plates The hammers impact on the coal crushing it coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer Duplex Assembly is recommended so that elements can be changed out coal mill roller assembly lalocandadipulcinellafr