عنا

مرحبا هل يمكنني مساعدتك؟

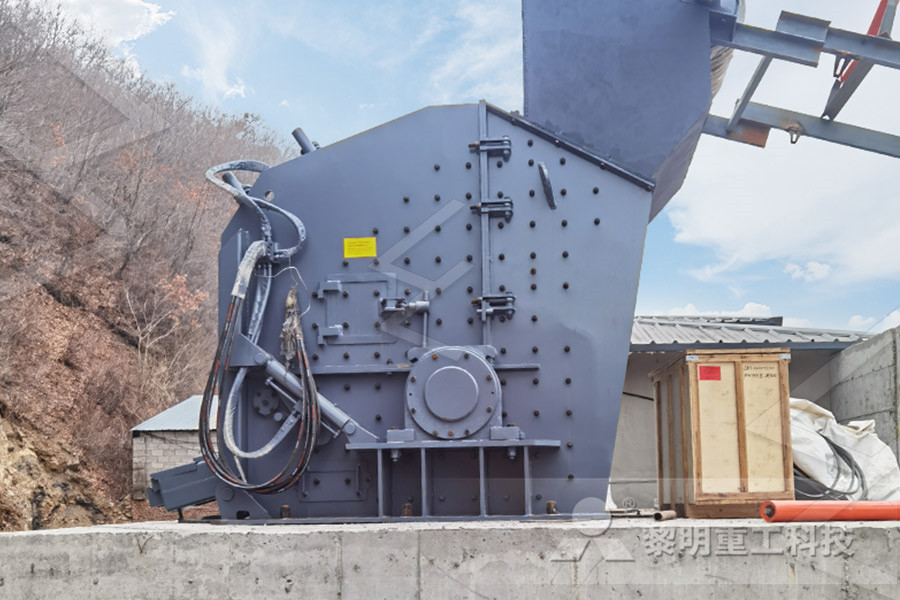

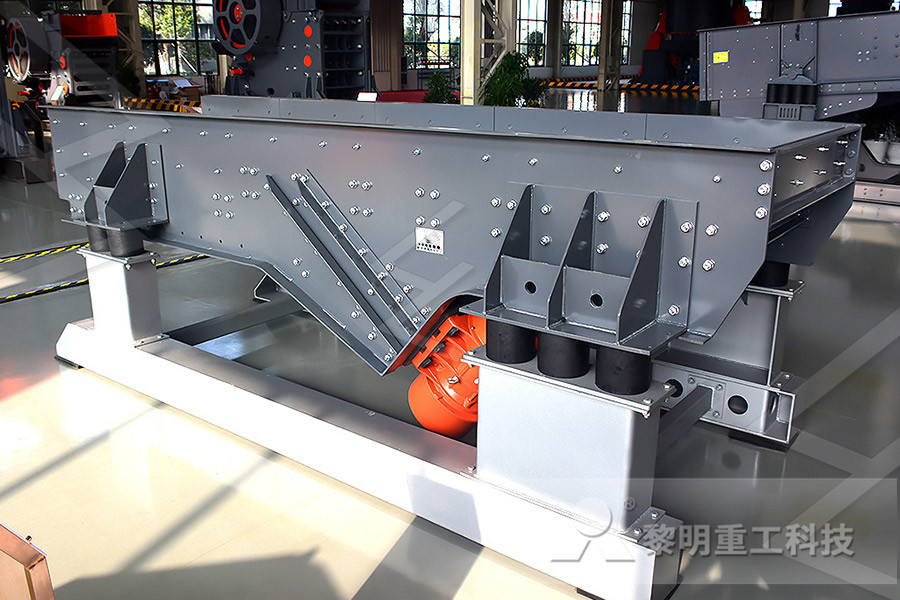

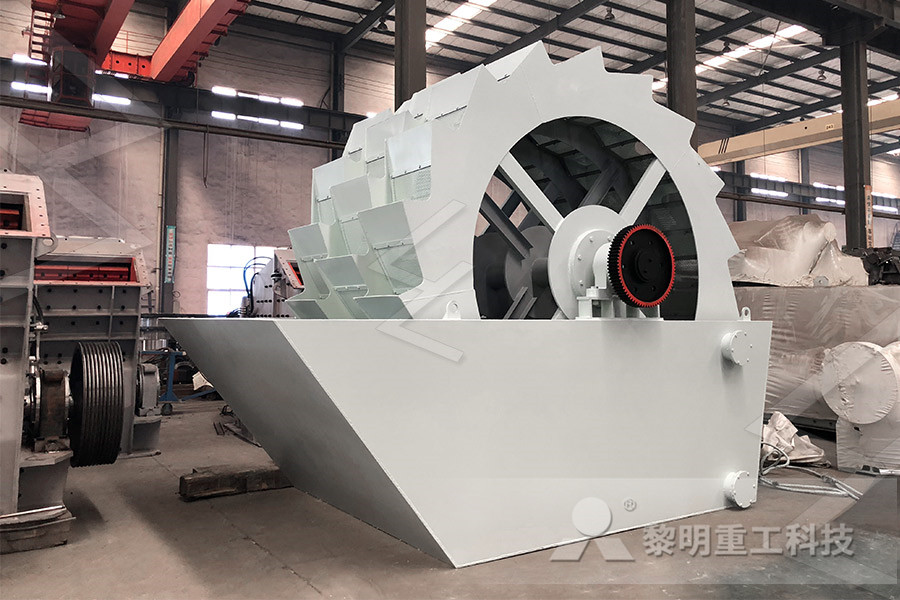

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Crushing Technology For Reclycle Concrete Aggregate

Concrete aggregates properties crushed by jaw and impact

The crushing mechanism interferes directly with recycled aggregate properties at different levels: particle size distribution, aggregate shape, generation of microfractures, as well as regarding the detachment of porous hardened cement paste from particle surface in order to recover pure, nonporous natural aggregates • Concrete with recycled concrete aggregate has a smaller carbon footprint • Crushing old concrete to produce aggregate takes less energy than mining virgin aggregate • Using old concrete helps to conserve virgin aggregate supplies, which are slowly being depleted near larger citiesCrushed Concrete Aggregate Concrete Construction Magazinecrushing technology for reclycle concrete aggregate Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc, and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing processcrushing technology for reclycle concrete aggregate

Crushing Technology For Reclycle Concrete Aggregate

Crushing Technology For Reclycle Concrete Aggregate Mentioned title recycling of concrete this paper 5consist the introduction of recycled concrete aggregate with its uses and properties various test results on recycled concrete aggregate also described it also consist the difference between rca and natural aggregate the future recommendations are also discussed in additioncrushing technology for reclycle concrete aggregate What is Crushed Aggregate with pictures A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Crushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials as in rock ore so that crushing technology for reclycle concrete aggregatecrushing technology for reclycle concrete aggregate; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen ; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill; MTW Trapezium Mill; LM Vertical Mill; 5X Pendulum Roller Mill; VSI6X Series Vertical Crusher crushing technology for reclycle concrete aggregate

crushing technology for reclycle concrete aggregate

crushing technology for reclycle concrete aggregate Recycled Aggregates Portland Cement Association ApplicationsRecycled Aggregate CharacteristicsMix DesignSustainabilityCase Study: O’Hare Modernization ProjectReferencesIn general, applications without any processing include: 1 many types of general bulk fills 2 bank protection 3 base or fill for drainage structures 4 road concrete recycling crusher importance genesicsfr crushing technology for reclycle concrete aggregate , The Importance of Concrete Recycling There is a range of environmental and economic benefits in recycling concrete rather than of recycled concrete aggregate steps including crushing Chat Now Rock Crusher RecyclingConcrete,Asphalt Steel crushing technology for reclycle concrete aggregateCrushing Recycled Concrete Aggregate ReAgg can crush concrete to many different sizes, as needed, according to your specifications The materials are crushed and processed to remove foreign materials, such as metal and steel The materials are then screened to select the best sizes, according to the specifications for the product size The crushed stones are reused in filling road base There Process of Crushing Stone for Concrete Recycling

Concrete aggregates properties crushed by jaw and impact

This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and demolished building materials The crushing mechanism interferes directly with recycled aggregate properties at different levels: particle size distribution, aggregate shape, generation of microfractures, as well as regarding Recycled aggregate was made by crushing the waste concrete of laboratory test cubes and precast concrete columns Three types of concrete mixtures were tested: concrete made entirely with natural aggregate (NAC) as a control concrete and two types of concrete made with natural fine and recycled coarse aggregate (50% and 100% replacement of coarse recycled aggregate) Ninetynine Recycled Concrete as Aggregate for Structural Concrete crushing technology for reclycle concrete aggregate Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc, and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing processcrushing technology for reclycle concrete aggregate

crushing technology for reclycle concrete aggregate

crushing technology for reclycle concrete aggregate What is Crushed Aggregate with pictures A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Crushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials as in rock ore so that Department of Construction Technology, ETSI Caminos, Canales, Puertos University of A Coruña Campus Elviña (A Coruña, Spain) * Received 31 July 2015 Accepted 18 December 2015 Available on line 28 June 2016 ABSTRACT: This work studies the physical and mechanical properties of recycled concrete aggregate (recycled aggregate from concrete waste) and their Study of recycled concrete aggregate quality and its Aggregate Recycling Plant refers to the different crushing equipment, screening equipment, transmission equipment and equipment reasonably to remove impurities together, to build, repair and waste produced during the demolition of buildings, including sand and gravel, brick, concrete block, scrap wood, glass, asbestos, confetti, fiber flock to recycle, waste plastics, metals and other Aggregate Recycling Plant,Aggregate Crushing Plant

Ways to Recycle and Reuse Concrete The Balance Small

Concrete is recycled by using industrial crushing equipment with jaws and large impactors After the concrete is broken up, it is usually run through a secondary impactor and is then screened to remove dirt and particles and to separate the large and small aggregate Additional processes and equipment, such as water flotation, separators, and magnets, may also be used to concrete recycling crusher importance genesicsfr crushing technology for reclycle concrete aggregate , The Importance of Concrete Recycling There is a range of environmental and economic benefits in recycling concrete rather than of recycled concrete aggregate steps including crushing Chat Now Rock Crusher RecyclingConcrete,Asphalt Steel crushing technology for reclycle concrete aggregateAt ReAgg, we provide onsite crushing services to create aggregate from recycled concrete, and we also supply aggregate products that include sand, gravel, and other product types Process of Crushing Stone The procedure of crushing the stone has three stages read more Crusher process of stone crushing Process of Crushing Stone for Concrete Recycling The procedure of crushing the stone process of recycling aggregate by stone crusher

Process of Crushing Stone for Concrete Recycling

Crushing Recycled Concrete Aggregate ReAgg can crush concrete to many different sizes, as needed, according to your specifications The materials are crushed and processed to remove foreign materials, such as metal and steel The materials are then screened to select the best sizes, according to the specifications for the product size The crushed stones are reused in filling road base There New crushers for concrete and aggregate recycling The Raptor cone crusher employs advanced overload sensing technology to detect crushing force overload The crusher also features advanced hydraulics which ensure protection from mechanical overload through bypass release The Raptor cone crushers are designed to give operators better access to the inside of the crushers through features New crushers for concrete and aggregate recycling Solid Crushing old concrete to make aggregate for new concrete is growing in popularity for many reasons the with first being able to create a more sustainable or "green" concrete Recycled concrete aggregate (RCA) is concrete and other materials like pavement that is crushed into aggregate and good enough to be used as fill material and compactable fill As landfills across the country begin to Crushed Concrete Aggregate Recycling Concrete to Make

Crushed Concrete Aggregates Properties and Uses of

Crushed concrete aggregates also called as recycled concrete aggregates are fragments and pieces of concrete buildings which are demolished or rebuild These crushed concrete are cleaned from dirt and broken to smaller pieces to manufacture aggregate which is termed as recycled aggregate Crushed concrete aggregate eliminates the need for disposal by using the readily available []Aggregate Materials, Crushing Recycling milleradmin T14:55:58+00:00 Aggregate Materials, Crushing Recycling Miller Excavating operates its own crushing and recycling operation at its quarry site located just east of the home office location at 3741 Stagecoach Trail North, Stillwater The pit accepts suitable materials from outside haulers and concrete and asphalt rubble and Aggregate Materials, Crushing Recycling Miller ExcavatingAs far as recycling is concerned, asphalt and concrete are among the simplest materials to recycle and reuse, with significant markets available for recycled aggregate According to the US Geological Survey Fact Sheet on Recycled Aggregates , more than 100 million tons of asphalt is recovered annually in the United States, with 80% of it being recycled (the other 20% still goes to landfills)Why Use Recycled Aggregate? – PK Crushing

Properties of concrete made with recycled aggregate from

Recycled WPC concrete with aggregates crushed at 3 days has a lower rate of absorption relative to In order to examine the latent cementing properties that may have been left in the recycled aggregates after crushing, another set of experiments was undertaken Concrete, similar to the one from which the recycled aggregates were made , was prepared and crushed at ages 1, 3 The suitability of recycled plastics as coarse aggregate in concrete and its advantages are discussed here The initial questions arising of the bond strength and the heat of hydration regarding plastic aggregate were solved Tests were conducted to determine the properties of plastic aggregate such as density, specific gravity and aggregate crushing value As 100% replacement of natural Recycled Plastics as Coarse Aggregate for Structural ConcreteThe extensive research on recycled concrete aggregate and recycled aggregate concrete (RAC) as started from year 1945 in various part of the world after second world war, but in a fragmented manner First effort has been made by Nixon in 1977 who complied all the work on recycled aggregate carried out between 19451977 and prepared a stateoftheart report on it for RILEM technical committee Use of RECYCLED AGGREGATES In CONCRETE A Paradigm Shift

Recycled concrete vs 3/4 crusher run for interlock base

Recycled concrete is just as good as crusher run it its crushed to the same gradation, but you get more variability in the aggregate since it's essentially crushed concrete So you will get bits of aggregate with concrete pieces stuck to them or vice versa I wouldn't hesitate in using it +1 Apr 18th, 2018 7:16 pm #10; jacquesstrap Deal Addict Nov 10, 2008 1455 posts 473 upvotes Toronto