عنا

مرحبا هل يمكنني مساعدتك؟

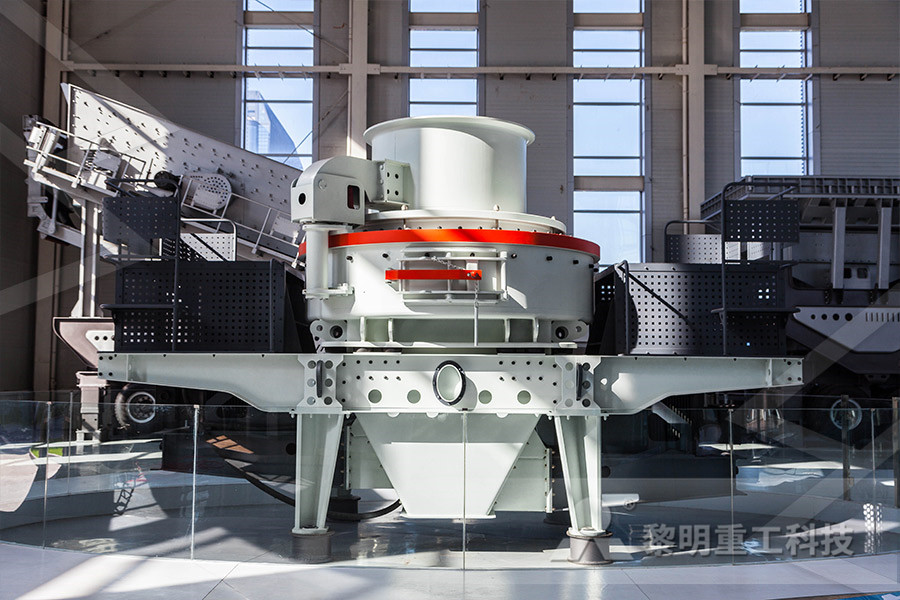

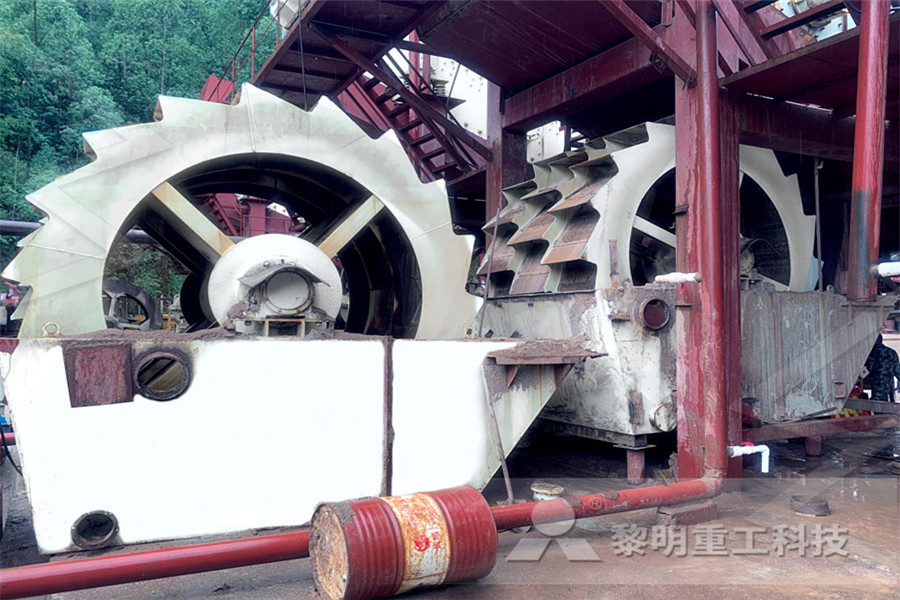

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

parts of stirred grinding machine

Parts of a Grinding machine and their functions

This grinding machine part consists of a grinding wheel and a driving motor The wheel head is mounted on a slide at the rear end of the base and moves perpendicularly to the table ways This is done by power or hand when feeding the grinding wheel to the work The most commonly used among the three is Surface Grinding Machine Now lets see different parts of Surface Grinding Machine and their function Main parts of Grinding Machines are : 1) BaseGrinding Machine Parts And Functions Mechanical WalkinsMaterials successfully ground in stirred mills Aluminum Oxide Aragonite Barite Blast Furnace Slag Calcined Bauxite Calcite Calcium Carbonate Clay Coal – oil Coal – water Coal Tar Sludge Coke – oil Copper Molybdenum Copper Concentrate Copper Ore Copper Slag CopperLeadZinc Ore Stirred mills for wet grinding

parts of stirred grinding machine

Commercial Grinding Machine Parts Industrial Lathe Parts To prevent machine ‘down time’ we recommend purchasing and storing commonly worn and any critical parts for your machine at your facility Accessories Upgrades and Replacements In addition to repairing and replacing parts, we also offer parts to upgrade your machine for higher degrees of precision, efficiency, and effectiveness Major Parts of the Universal CenterType Cylindrical Grinder Major parts of the machine include the bed, slide, swivel table, headstock, footstock, and wheelhead Bed The bed is the main structural component and is responsible for the rigidity of the machine tool The bed supports the slide, which in turn supports the swivel tableIDENTIFYING MACHINE PARTS AND THEIR FUNCTIONS – Cad cam Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding Grinding Machine: Types, Parts, Working Operations (With

Stir Grinder Factory, Custom Stir Grinder OEM/ODM

Looking for stir grinder factory direct sale? You can buy factory price stir grinder from a great list of reliable China stir grinder manufacturers, suppliers, traders or plants verified by a thirdparty inspector Source with confidence Sometimes circular parts are centered on this grinder; the resulting concentric scratch pattern is excellent for metaltometal seals of mating parts Accessory spindles and special wheel shaping (dressing) add to the versatility of this (reciprocating table version) grinding machine (Figure L6) Vertical spindle grinding machines are often seen in large sizes (Figure L7)Cylindrical TYPES OF GRINDING MACHINES – Cad cam Engineering WorldWidegrinding stirred grinding mill crusher grinder machine Stirred mills for milling grinding Stirred mills offer fine and ultrafine grinding that outperform similar technologies in terms of design cost availability and footprint For fine and ultrafine grinding stirred mill and tower Get Price; vertical stirred media millsmpulele The stirred mills are charged with a media size of 10–12 stirred grinding tower pbspomagampl

Grinding Machine Parts And Functions Mechanical Walkins

Main parts of Grinding Machines are : 1)Base 2)Table 3)Column 4)Abrasive Wheel 5)Wheel Guard 6)Abrasive Wheel Head7)Three types of traversing wheels 8)Coolant Supply Nozzle Functions of the above stated parts of grinding machine are stated below :1) Base : The base is bottom most part of the grinding machine It is generally made of cast iron It provides support to rest part Sometimes circular parts are centered on this grinder; the resulting concentric scratch pattern is excellent for metaltometal seals of mating parts Accessory spindles and special wheel shaping (dressing) add to the versatility of this (reciprocating table version) grinding machine (Figure L6) Vertical spindle grinding machines are often seen in large sizes (Figure L7)Cylindrical TYPES OF GRINDING MACHINES – Cad cam Engineering Grinding spindle drives of surface grinding machines require steplessly adjustable numbers of rotation speed up to about 10,000 min –1 In dependence on the grinding wheel diameter, cutting speeds of about 400 m/s are achieved so that high speed machining conditions are reached The spindle power of surface grinders depends on the field of application and may amount up to 80 kWGrinding Machines an overview ScienceDirect Topics

Grinding D98 2 Micron Powder Grinder Machine Wet Stirred

Dry grinder machine is not able to achieve this product fineness with economical energy efficiency 1 Good combination of different grinding balls makes coarse partiles stay in down part of grinding chamber 2 Small grinding balls shear the particles in the middle part of grinding chamber 3 Fine particles will flow up from gaps between Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns This provides up to a 40% higher energy efficiency With the Vertimill® simple and robust design, limited liner replacement is required This also allows for upt to 95% or greater uptime for more productivity and Vertimill® Pneumatic Operated Multipurpose Grinding Machine Clamps are used at the connecting parts to prevent leakage In threaded parts thread seals are used to prevent leakage Here the compressed air from the compressor firstly enters the control unit In the control unit the pressure of the air is controlled and sent to the barrel to rotate the fan Pneumatic Operated Multipurpose Grinding Machine

Machine tool Basic machine tools Britannica

Modern grinding machines grind hard or soft parts to tolerances of plus or minus 00001 inch (00025 millimetre) The common types of grinding machines include the following: (1) plain cylindrical, (2) internal cylindrical, (3) centreless, (4) surface, (5) offhand, (6) special, and (7) abrasivebelt Power saws Learn from a saw filer what working in a saw mill is like Description of the The pneumatic grinding is a metal grinding machine tool designed to cut/grind metal by applying pneumatic pressure The machine is exclusively intended for mass production and they represent the fastent and more efficient way to cut a metal The slow speed operation is occurs in a grinding operation This machine is a multipurpose machinePNEUMATIC SOLENOID OPERATED GRINDING MACHINE 2 The drilling machine is defined as a machine which is used to make a circular hole, a tool used to drill the holes of different size and other related operations using a drill bit The drilling machine is one of the most important machines in a workshop As regards its importance it is second only to the lathe machinesHoles were drilled by the Egyptians in 1200 BC about 3000 years ago by Drilling Machine [Parts, Types, Tools, Operations] with PDF

Frequent problems during grinding – grindaix GmbH

Only part of the heat generated is taken up by the part, thereby lowering the risk of grinding burn considerably Frequently, coolant lubricant is used generously in machine tools in an attempt to achieve a process with zero grinding burn However, even massive use of coolant lubricant will not succeed in preventing grinding burn if it is unable to reach the machining site in a targeted way Sometimes circular parts are centered on this grinder; the resulting concentric scratch pattern is excellent for metaltometal seals of mating parts Accessory spindles and special wheel shaping (dressing) add to the versatility of this (reciprocating table version) grinding machine (Figure L6) Vertical spindle grinding machines are often seen in large sizes (Figure L7)Cylindrical TYPES OF GRINDING MACHINES – Cad cam Engineering The basic parts of surface grinding machine are: Base; Hand Traversing Wheel; Cross Slide Handwheel; Work Table; Column; Wheel Head; Vertical Feed Hand Wheel; Wheel Guard; Abrasive Wheel; Coolant; The functioning of above Parts are as follows Base: It acts as a support for the entire assembly and also acts as an absorber of vibrations Hand Traversing Wheel: This traversing wheel is Surface Grinding Machine: Definition, Parts, Working

Vertimill®

Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns This provides up to a 40% higher energy efficiency With the Vertimill® simple and robust design, limited liner replacement is required This also allows for upt to 95% or greater uptime for more productivity and MM Tool and Machinery 3362 South Main Street Salt Lake City, Utah 84115Makita Grinder Parts Diagram and Parts ListGrinding spindle drives of surface grinding machines require steplessly adjustable numbers of rotation speed up to about 10,000 min –1 In dependence on the grinding wheel diameter, cutting speeds of about 400 m/s are achieved so that high speed machining conditions are reached The spindle power of surface grinders depends on the field of application and may amount up to 80 kWGrinding Machines an overview ScienceDirect Topics

Types of Grinding Machine mech4study

Today we will discuss about main type of grinding machine Grinding is an another type of machining process which is used to for finishing purpose This process is used as secondary machining process because it is always done after a primary machining on other machine tool like lathe, milling machine etc We have discussed about grinding process in our last article If you haven’t read Modern grinding machines grind hard or soft parts to tolerances of plus or minus 00001 inch (00025 millimetre) The common types of grinding machines include the following: (1) plain cylindrical, (2) internal cylindrical, (3) centreless, (4) surface, (5) offhand, (6) special, and (7) abrasivebelt Power saws Learn from a saw filer what working in a saw mill is like Description of the Machine tool Basic machine tools Britannica The drilling machine is defined as a machine which is used to make a circular hole, a tool used to drill the holes of different size and other related operations using a drill bit The drilling machine is one of the most important machines in a workshop As regards its importance it is second only to the lathe machinesHoles were drilled by the Egyptians in 1200 BC about 3000 years ago by Drilling Machine [Parts, Types, Tools, Operations] with PDF

Grinder Safety Hazards, Precautions, PPE Safety Notes

Grinder Machine Hazards All types of grinding machines, whether pedestal, bench mounted, freestanding or portable, can be potentially hazardous if they are not well maintained and used correctly In addition to the common hazards of flying particles, dust and sparks, shattering abrasive wheel while in Motion can cause severe injury to both the user and others To avoid a potential