عنا

مرحبا هل يمكنني مساعدتك؟

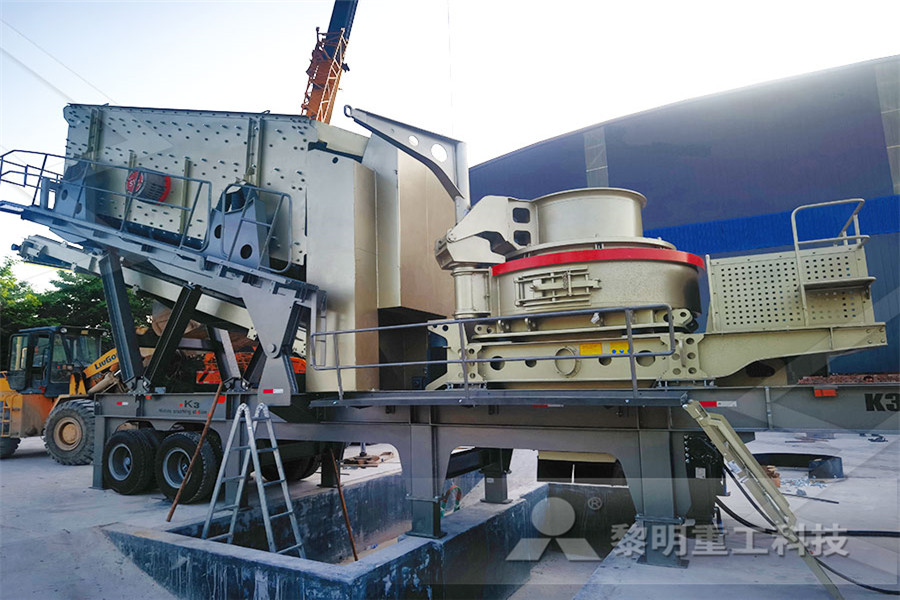

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

differences between carbide and steel rock tools

Difference Between Carbide and High Speed Steel Compare

The key difference between carbide and high speed steel is that the carbide is extremely hard and abrasion resistant and therfore, the tools made from carbide last longer than that made from high speed steel However, the hardness and abrasion resistance of high speed steel is superior to that of common carbon steel and tool steel The main difference between them is mainly listed below: The red hardness of highspeed steel is 650℃, but the Carbide steel can reach 8001000℃ Carbide steel has more high cutting speed and is 4 7 times higher than high – speed steel Carbide is much harder, so it has a longer tool life and What is the difference between high speed steel tools and Steel bits are cheaper, but carbidetipped router bits maintain a sharper cutting edge, produce a better finish, and provide cleaner and smoother cuts They also withstand very high temperatures better than steel, allowing for faster machining Carbide Tipped vs Steel, No Contest! JavaScript seems to be disabled in your browserCarbide Tipped vs Steel, No Contest! Amana Tool Full

Carbide Tipped vs High Speed Steel and Solid Carbide

Carbide cracks stopped in steel body pocket rather than shattering the entire tool; Reduced scrap machine downtime as even a cracked carbide tipped tool keeps cutting; A shattered solid carbide tool often damages the piece being machined; ADVANTAGE #3: Tipped tools usually cost less than solid carbide; Expensive carbide only used for cutting edge chip forming surface ; Often utilize A minute to learn the difference between cemented carbide and superalloy and tool steel The cutting speed of new cemented carbide tools is now several hundred times that of carbon steel Cemented carbide can also be used to make rock drilling tools, mining tools, drilling tools, measuring gages, wear parts, metal grinding tools, cylinder liners, precision bearings, nozzles, etc A minute to learn the difference between cemented carbide As nouns the difference between steel and carbide is that steel is (uncountable) an artificial metal produced from iron, harder and more elastic than elemental iron; used figuratively as a symbol of hardness while carbide is (chemistry) any binary compound of carbon and a more electropositive element As a adjective steel is made of steelSteel vs Carbide What's the difference? WikiDiff

High Speed Steel versus Carbide in Metal Cutting Why HSS

High Speed Steel is a high carbon tool steel, containing a large dose of tungsten A typical HSS composition is: 18% tungsten, 4% Chromium, 1% Vanadium, 07% carbon and the rest, Iron HSS tools have a harness of 6264 Rc The addition of 5 to 8% cobalt to HSS imparts higher strength and wear resistance Typically, drills made with the addition of cobalt (popular grade types M15 and M42) are Highspeed steel (HSS) is the standard for metal cutting tools since the nineteenthirtues It is often used as a starting point for comparison because of its toughness, wear resistance, and sufficient hardness for general purpose metal cutting, mWhat is the difference between HSS and carbide tools? Quora Machine tools plays a very crucial role in manufacturing of metal components through machining Computerized numerical control () machines are prominently used for machining of metal components which requires high precision for producing compleWhat is the difference between HSS and solid carbide tools

How to tell Carbide from HSS Practical Machinist

Recently acquired a large lot of tools, etc including a bunch of endmills I have HSS and Carbide mills in the shop and after looking at them, I find it very hard to tell which is which is they're not properly labelled I guess I could take a file to them in a rough estimate but Carbide lasts longer between sharpenings but does not take as good of an edge, is brittle, and requires diamond sharpening equipment HSS (and other steel alloys) take a sharper edge and make a nicer cut, but dull faster They are more easily sharpened and can be done by hand in some cases Which you choose depends on a lot of factors Insert tooling? Long production runs? Short runs? Small Carbide Versus HSS Tooling WOODWEBIn a nutshell, carbide is a lot harder and as a result, more brittle That final hone crumbles the edge, whereas HSS burrs rather than crumbles, ultimately leaving a sharper edge However, as you noted, the life of carbide is far superior to HSS steel, so your slightly duller tool is going to be slightly duller for a long time The comparison Sharpness of High Speed Steel Versus Carbide Tooling

FAQ Band Saw Blades: BiMetal, Carbon, Carbide Blades

They are used on band saws to cut carbon steel, tool steel, structural steel, stainless steel, pipes and tubes, die steel, angles and flat stock, and mixed metal applications Our clients who use these metal cutting bandsaw blades include steel service centers, small to large manufacturers, fabricators, maintenance shops, job shops, tool and die shops, and anyone interested in saw cutting a Highspeed steel (HSS) is the standard for metal cutting tools since the nineteenthirtues It is often used as a starting point for comparison because of its toughness, wear resistance, and sufficient hardness for general purpose metal cutting, mWhat is the difference between HSS and carbide tools? QuoraCarbide button bits – Available in 1 3 ⁄ 8" to 225" diameter and prove to be more effective in very hard rock, especially when using the heavier classes of rock drills All steel – Good for concrete and very soft rock applications or occasional to rare usage You can expect a much shorter service life than a carbide bit, but there are H D Steel and Bits Rock Drill Bits

Comparing Woodturning Tool Steels Craft Supplies USA

What is the difference between M2 high speed steel and M42 high speed steel? Does powdered metallurgy steel hold an edge longer than other turning tools? Is there really a difference? What tool steel is best for you? With so many modern tool steels available today, it’s easy to get confused In this video we discuss the benefits of each steel Hard and potentially brittle materials such as glass, tool steel, and cemented carbide are most suited to the finer gritted abrasive What grinding wheel grade should I choose? The grade indicates the relative holding power of the bond, which holds abrasive grains in a wheel Soft Grades: • For hard materials such as hard tool steels carbides • For large areas of contact • For rapid Which Grinding Wheel Should I Choose? Norton Well it’s not like a carbide toothed blade where the extra piece of carbide is brazed to each tooth (now you understand why carbidetip band saw blades cost so much more) These photos clearly show the difference between the tipped blades and the impregnated blades The first photo shows a tooth on a carbide tip band saw blade , you can clearly see the added piece of carbide that’s brazed Band Saw Blades With Carbide Teeth, Not Tips Popular

How to tell Carbide from HSS Practical Machinist

Recently acquired a large lot of tools, etc including a bunch of endmills I have HSS and Carbide mills in the shop and after looking at them, I find it very hard to tell which is which is they're not properly labelled I guess I could take a file to them in a rough estimate but Plain carbon steel tools, containing about 09% carbon and about 1% manganese, hardened to about 62 Rc, are widely used for woodworking and they can be used in a router to machine aluminium sheet up to about 3mm thick 2 High Speed Steel (HSS) HSS tools are so named because they were developed to cut at higher speeds Developed around 1900 HSS are the most highly alloyed tool steels The Cutting Tool MaterialsCarbide lasts longer between sharpenings but does not take as good of an edge, is brittle, and requires diamond sharpening equipment HSS (and other steel alloys) take a sharper edge and make a nicer cut, but dull faster They are more easily sharpened and can be done by hand in some cases Which you choose depends on a lot of factors Insert tooling? Long production runs? Short runs? Small Carbide Versus HSS Tooling WOODWEB

A Comprehensive Guide To Pros and Cons of Carbide Tools

As a shop engineer, you may already know that the difference between carbide tools and highspeed steel can make a significant difference in the quality of production and the speed at which you can turn out product There are variances between the tolerances and effectiveness of both materials, and the difference can make a significant impact on your processes, depending on your specific Carbide button bits – Available in 1 3 ⁄ 8" to 225" diameter and prove to be more effective in very hard rock, especially when using the heavier classes of rock drills All steel – Good for concrete and very soft rock applications or occasional to rare usage You can expect a much shorter service life than a carbide bit, but there are H D Steel and Bits Rock Drill Bits What is the difference between M2 high speed steel and M42 high speed steel? Does powdered metallurgy steel hold an edge longer than other turning tools? Is there really a difference? What tool steel is best for you? With so many modern tool steels available today, it’s easy to get confused In this video we discuss the benefits of each steel Comparing Woodturning Tool Steels Craft Supplies USA

Which Grinding Wheel Should I Choose? Norton

Hard and potentially brittle materials such as glass, tool steel, and cemented carbide are most suited to the finer gritted abrasive What grinding wheel grade should I choose? The grade indicates the relative holding power of the bond, which holds abrasive grains in a wheel Soft Grades: • For hard materials such as hard tool steels carbides • For large areas of contact • For rapid Many times, steel tools will come covered with a carbide to provide it with extra strength and durability Carbide comes in several different numbered gradesranked from soft to hard Each has its own unique properties that affect its ability to absorb shock, handle wear and tear, and withstand heat brought on by friction Carbide grades Carbide comes in four grades of durabilityC1 to C17 What is C2 C3 Carbide? eHow Well it’s not like a carbide toothed blade where the extra piece of carbide is brazed to each tooth (now you understand why carbidetip band saw blades cost so much more) These photos clearly show the difference between the tipped blades and the impregnated blades The first photo shows a tooth on a carbide tip band saw blade , you can clearly see the added piece of carbide that’s brazed Band Saw Blades With Carbide Teeth, Not Tips Popular

C2 and C6 carbide The Home Shop Machinist Machinist's

What's the difference between C2 and C6 carbide? I've noticed that they sell carbide tipped cutters with C2 carbide and C6 carbidewhat are the different types used for? Is C2 for cast iron and certain nonferrous materialsi seem to remember that from somewhere? Last edited by Fasttrack; 09052006, 10:47 PM Tags: None CCWKen Senior Member Join Date: Jan 2003; Posts: 8567; Share The silicon carbide stones made by Norton are called Crystolon stones These stones are also labeled fine, medium, and coarse They are usually gray in color While these stones will not produce an edge as fine as the India or natural stones, the fast cutting makes them ideal for initial coarse sharpening Because they sharpen quickly, it a common practice to use the Coarse Crystolon and then Difference in Sharpening Stone Materials Tungsten carbide is a type of steel mainly comprising of cobalt as well as tungsten carbide The cobalt will act as a binder and help enhance shock resistance when drilling The shock resistance provided will depend on the percentage of cobalt used to manufacture the product, and usually a small amount of wax will be added to hold the materials together Tungsten carbide is a high Difference between Cobalt and Carbide drill bits