عنا

مرحبا هل يمكنني مساعدتك؟

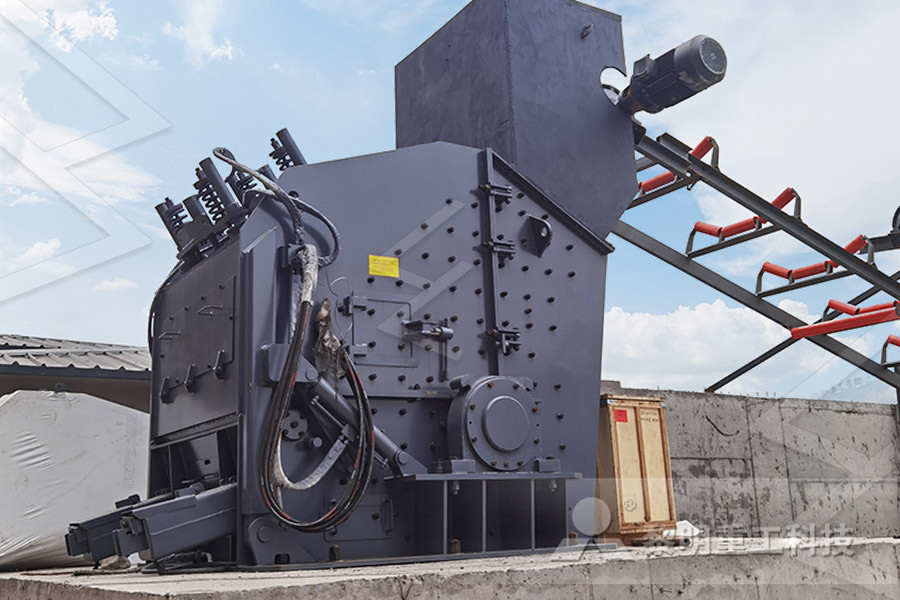

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill working principle process

The working principle of ball mill Meetyou Carbide

The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal forceThe operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsThe operating principle of the ball mill Primo Pizza Operating Principle of Ball Mills While a number of mill types have come up in the market due to this process, the operating principle of every product distributed by ball mill manufacturers remains the same The mill chamber is filled with balls and input materials at an angle of 3050 degrees As the chamber rotates the material within it collides with the sliding chamber walls and the Operating Principle of Ball Mills Digitalmaurya

Ball Mill Working Principle And Main Parts

34 rows The ball mill host comprises a cylinder body, cylinder body made of inlaid useful wear A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect Topics

Ball Mill Operation Grinding Circuit Startup Shutdown

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing MetallurgyATTRITORS AND BALL MILLS HOW THEY WORK Robert E Schilling , M Yang UNION PROCESS INC Akron, Ohio Presented by Robert "Bob" Schilling Presented at the Philadelphia Society For Coatings Technology Inc Eastern Training Conference and Show May 9, 2000 1 ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle ATTRITORS AND BALL MILLS HOW THEY WORK Union Process

Operating Principle of Ball Mills Digitalmaurya

Operating Principle of Ball Mills While a number of mill types have come up in the market due to this process, the operating principle of every product distributed by ball mill manufacturers remains the same The mill chamber is filled with balls and input materials at an angle of 3050 degrees As the chamber rotates the material within it collides with the sliding chamber walls and the Ball Mill Working Principle Grinding is usually performed wet, although in certain applications dry grinding is used When the mill is rotated, the mixture of medium, ore, and water, known as the mill charge, is intimately mixed; the medium comminuting the particles depends on the speed of rotation of the mill and the shell liner structure Generally, grinding in mineral processing is a ball mill working principle Henan Deya Machinery Co, LtdCement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamber It is lined with classifyingtype mill shell liners and provided with finer ball charge Classifying The structure and working principle of cement ball mill

Ball Mill Working Principle Process torengineeringde

Ball Mill Working Principle Process Z Niejednego Garnka Ball Mill Working Principle Process The operating principle of the ball mill consists of following steps In a continuously operating ball mill feed material fed through the central hole one of the caps into the drum and moves therealong being exposed by grinding media The material grinding occurs during impact falling grinding balls and Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the Ball Mill Operation Grinding Circuit Startup Shutdown BALL MILL 3 TABLE OF CONTENT: INTRODUCTION DEFINITION BASIC PRINCIPLE CONSTRUCTION WORKING ADVANTAGES AND DISADVANTAGES APPLICATIONS EQUATIONS 4 BALL MILL INTRODUCTION: • It is efficient tool for grinding many materials into fine powder • There are two types of grinding, the dry process and wet process 5Ball Mill SlideShare

Ball Mill Crusher Working Principleball Mill

Ball Mill Working Principle Ball mill is one of the high fine grinding machine is widely used in industrial production there are a lot of its type it is widely used in mineral processing building materials and chemical industry etc but do you know how does it work this paper will mainly explain the working principle of ball mill for youATTRITORS AND BALL MILLS HOW THEY WORK Robert E Schilling , M Yang UNION PROCESS INC Akron, Ohio Presented by Robert "Bob" Schilling Presented at the Philadelphia Society For Coatings Technology Inc Eastern Training Conference and Show May 9, 2000 1 ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle ATTRITORS AND BALL MILLS HOW THEY WORK Union Process Ball Mill Working Principle Process In India Ball mill working principle process ball mill wikipedia a ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sinteringit works on the principle of impact and attrition size reduction is done by impact as theBall Mill Working Principle Process In India

ball mill working principle process in ghana

ball mill working principle process in ghana The working principle of ball mill Meetyou Carbide,May 22 2019 22 May 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated the grinding body ball and the object to be polished material installed in the cylinder are rotated by the cylinder under the action of friction and Operating Principle of Ball Mills While a number of mill types have come up in the market due to this process, the operating principle of every product distributed by ball mill manufacturers remains the same The mill chamber is filled with balls and input materials at an angle of 3050 degrees As the chamber rotates the material within it collides with the sliding chamber walls and the Operating Principle of Ball Mills DigitalmauryaCement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamber It is lined with classifyingtype mill shell liners and provided with finer ball charge Classifying The structure and working principle of cement ball mill

Working principle of ball mill and movement analysis of

Working principle of ball mill: The main working part of the ball mill is a rotating cylinder mounted on two large bearings and placed horizontally The cylinder is divided into several compartments with compartments, in which grinders of a certain shape and size are installed The grinding body is generally steel ball, steel forging, steel bar, pebble, gravel and porcelain ball, etc In order Ball Mill Working Principle Process Z Niejednego Garnka Ball Mill Working Principle Process The operating principle of the ball mill consists of following steps In a continuously operating ball mill feed material fed through the central hole one of the caps into the drum and moves therealong being exposed by grinding media The material grinding occurs during impact falling grinding balls and Ball Mill Working Principle Process torengineeringdeBall mill operating principleBall mill working principle to be chosen according to the grinding material material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body when the ball mill cylinder rotation time grinding body due to inertia and centrifugal force the effects of friction making it attached to the cylinder liner on the cylinder body away when takenBall Mill Operating Principle

The Component Of Ball Mill And Its Working Principle

Rolling Process Types Working Terminology And Working Principle Rolling works on same as any other metal forming process When a compressive force applied by a set of rolls on ingot or any other product like blooms or billets, plastic deformation takes place which decrease its cross section area and convert it into required shape Wet Energysaving Grate Ball Mill Yantai Jinpeng working Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding Improving the competences of the team plays a key role in the optimal utilisation of the grinding installation in your cement plant The operators and process engineers must be able to evaluate all the process variables in order to Grinding technology and mill operations Ball Mill Working Principle Process In India Ball mill working principle process ball mill wikipedia a ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sinteringit works on the principle of impact and attrition size reduction is done by impact as theBall Mill Working Principle Process In India

ATTRITORS AND BALL MILLS HOW THEY WORK Union Process

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E Schilling , M Yang UNION PROCESS INC Akron, Ohio Presented by Robert "Bob" Schilling Presented at the Philadelphia Society For Coatings Technology Inc Eastern Training Conference and Show May 9, 2000 1 ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle Ball Mill Working Principle Working principle of a ball mill koueiinternationalmep 29, 2013 working principle of ball mill crushermiracle overblog have always believed the whole idea behind blogging is simple placing anybody in a role that ball mill working principle and calculation crusher tw european trapezium millget priceVertical Ball Mill Working Principle