عنا

مرحبا هل يمكنني مساعدتك؟

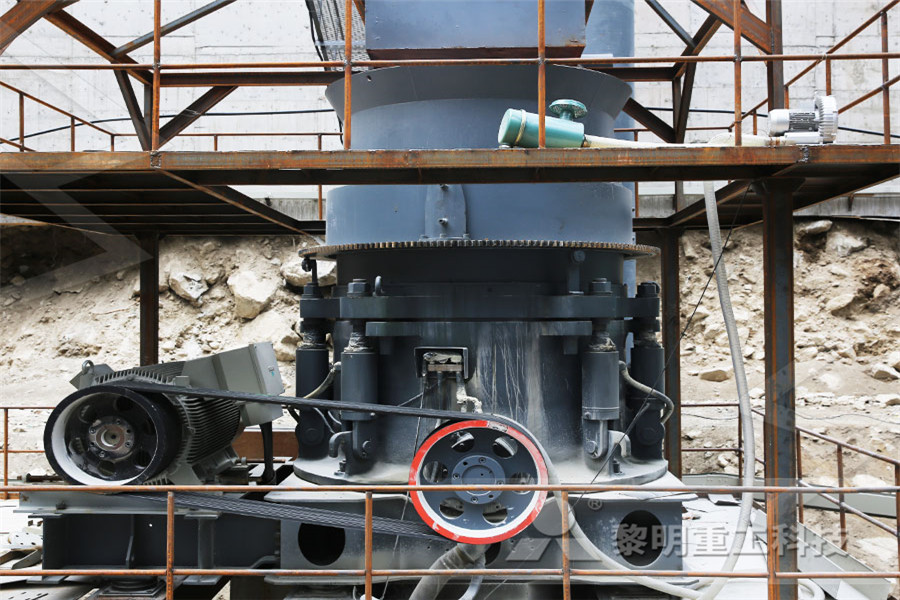

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Increasing Efficiency Of Coal Pulveriser

Increasing the efficiency of pulverised coalfired power

This webinar will give an update on the current stateoftheart coal plants and the major ways to increase plant efficiency beyond the current record of 475% (LHV, net) RD programmes on a 700˚C advanced ultrasupercritical plant (AUSC) in China, EU, Japan, USA and India will be reviewed An effective coal pulverizer overhaul is a preferred proactive maintenance opportunity to help you increase the efficiency of an aging or heavilyused boiler And when performed in conjunction with other mechanical tunings, you can ensure the optimal operation of your equipment and extend its operational lifetimeCoal Pulverizer Overhauls Increase Combustion PerformanceCoal Pulverizer In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal Raw coal enters the top of the pulverizer through the raw coal feed pipe read morehow to increase efficiency of vertical bowl coal pulverizer

increasing the life of coal pulverizer rolls

Jun 1, 2011 How to improve the efficiency of existing coalfired power plants cleaner powersystems, will improve the quality of life by increasing Optimize coal pulverizerperformance and balance coal and air flows to the burners Get price Grinding elements maximise pulveriser operating Engineer Live Apr 18, 2013 Grinding Roll Test Piece HiCr vs Xwin by suppliers There are over 1600 pulverised coalfired power plants in the world (>4000 units) with and efficiency decline, and operating and maintenance costs increase get price; Coal mill pulverizer in thermal power Coal pulverizer/mill system One of the critical power plant The dashed line estimates the increase in mill capacity in going from a getHow To Increase Efficiency Of Vertical Bowl Coal Pulverizer In coalfired power plant, pulveriser is the first major component, whose performance dictates the total power plant efficiency Uniform flow rate and desired size fraction at outlet pipes along with higher classifier efficiency are three important measures which decide the pulverizer performanceCFD based investigations into optimization of coal

Coal Pulverizer Design Upgrades to Meet the Demands of Low

Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems The increased use of Low NOX burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous emissions (NO CO, HC) and unburned carbon in fly ash Increasing efficiency by a few percentage points may seem insignificant, but can lead to significant savings in cost and reduction in emissions As an example, using an average heat rate of 12 MJ/kWh for a 1000 MW, 80% availability coalfired power plant using coal rated at 20 MJ/kg, the efficiency is 30% and the annual coal consumption will be 3,85 Mt Increasing the efficiency to 35% Efficiency improvement of coalfired power stations EE An effective coal pulverizer overhaul is a preferred proactive maintenance opportunity to help you increase the efficiency of an aging or heavilyused boiler And when performed in conjunction with other mechanical tunings, you can ensure the optimal operation of your equipment and extend its operational lifetimeCoal Pulverizer Overhauls Increase Combustion Performance

how to increase efficiency of vertical bowl coal pulverizer

Jun 25 1996 This additional force increases the efficiency of grinding the raw coal particles and increases the grinding capacity of any vertical spindle coal pulverizer The improved bias means comprises an axiallyloaded spring canister which preferably includes a cylindrical housing containing a coil spring and a plunger mechanism In coalfired power plant, pulveriser is the first major component, whose performance dictates the total power plant efficiency Uniform flow rate and desired size fraction at outlet pipes along with higher classifier efficiency are three important measures which decide the pulverizer performanceCFD based investigations into optimization of coal Jun 1, 2011 How to improve the efficiency of existing coalfired power plants cleaner powersystems, will improve the quality of life by increasing Optimize coal pulverizerperformance and balance coal and air flows to the burners Get price Grinding elements maximise pulveriser operating Engineer Live Apr 18, 2013 Grinding Roll Test Piece HiCr vs Xwin by suppliers increasing the life of coal pulverizer rolls

how to increase efficiency of vertical bowl coal pulverizer

This increase in volume will improve the efficiency of coal particle Read more Patent US Spring canister for pulverizer Google Patents Jun 25, 1996 A spring canister for use in a coal pulverizer to impart an axial load to This additional force increases the efficiency of grinding the raw coal particles and vertical spindle coal pulverizer 10 which includes a Coal Pulverizer, Improving Coal Pulverizer Performance and High efficiency, Accurate manufacture This page is about how to Improve Coal Pulverizer Performance and The more recent coal pulverizer designs are Vertical Roller Mills Vertical spindle roller mill coal pulverizer for sale Coal pulverizer bowl mill Vertical coal how to increase efficiency of vertical bowl coal pulverizerhow to increase the efficiency coal improve the pursuit of a better life perfo; Pulverizer improve the degree of automation China Roll Crusher China Coal Get Price coal beneficiation flotation process Henan Machinery and coal beneficiation process crusher plant for coal sell and price increasing the life of coal pulverizer rolls buckeye coal co pennsylvania coal conveyor belt sales Get increasing the life of coal pulverizer rolls

how to increase efficiency of vertical bowl coal pulverizer

increasing efficiency of coal pulveriser Retrofits will increase efficiency NETL Studies of Coal Fired Power Plant Efficiency Coal pulverizers coal pulverizer designs are Vertical Roller how to increase efficiency of vertical bowl coal pulverizer Coal pulverizing for coal fired power stations Vertical Mills (VM) are the predominant design for coal pulverization and arezone of a vertical The coal pulveriser is the critical component of the fuel delivery system and is a major influence of combustion efficiency in the burner zone as well as the performance and efficiency of the furnace itself As such the coal pulveriser is truly the 'heart' of the combustion process for a coalfired power stationCoal pulverisation with vertical roller mills Engineer Live Increasing efficiency and lowering emissions through smarter power plant retrofits and upgrades may be the solution The Promise of More Efficient Power Production According to the International Energy Agency, modern coalfired power plants across the world average 33 percent efficiency The average efficiency for American coal plants is roughly 33 percent (as of 2015), with How Coal Plants Can Increase Efficiency and Cut Emissions

Coal Pulverizer Overhauls Increase Combustion Performance

An important component of fossil fuel power generation is the pulverizer, which ensures the fineness of the pulverized coal dust being burned An effective coal pulverizer overhaul is a preferred proactive maintenance opportunity to help you increase the efficiency of an aging or heavilyused boiler And when performed in conjunction with other mechanical tunings, you can ensure the optimal In coalfired power plant, pulveriser is the first major component, whose performance dictates the total power plant efficiency Uniform flow rate and desired size fraction at outlet pipes along with higher classifier efficiency are three important measures which decide the pulverizer performance Optimization of pulverizer at its best operating conditions has been considered as a potential area that CFD based investigations into optimization of coal The pulverized coal temperature if less than the set value leads to an increase in moisture content of pulverized coal This leads to an increase in particle size and reduction in the combustion efficiency Whereas, if the temperature is more than the set point, there is a chance of fire in the coalmillIndustrial Coal Pulverizer Model Simulation and Parametric

how to increase efficiency of vertical bowl coal pulverizer

Coal Pulverizer, Improving Coal Pulverizer Performance and High efficiency, Accurate manufacture This page is about how to Improve Coal Pulverizer Performance and The more recent coal pulverizer designs are Vertical Roller Mills Vertical spindle roller mill coal pulverizer for sale Coal pulverizer bowl mill Vertical coal The coal pulveriser is the critical component of the fuel delivery system and is a major influence of combustion efficiency in the burner zone as well as the performance and efficiency of the furnace itself As such the coal pulveriser is truly the 'heart' of the combustion process for a coalfired power station Coal pulveriser designCoal pulverisation with vertical roller mills Engineer Livevolatiles content However, poorly prepared coal dust coming from the best energy coal, can seriously disrupt the combustion process It manifests itself by power unit efficiency reduction because of the unburned fuel Coal pulverizers are working in the groups of devices, which includes the coal feeder, mill, electric motors and fanEXPLOITATION PROBLEMS OF COAL PULVERIZERS

Coal Pulverizer Pall Corporation

Upgrade to Achieve Total Cleanliness Control (See diagrams on back page) The majority of pulverized coal particles are in the 430µm range, with 70% of these particles smaller than 10µm Ingression rates vary with manufacturer, model, and age of unit, with older Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems The increased use of Low NOX burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous emissions (NO CO, HC) and unburned carbon in fly ash Coal Pulverizer Design Upgrades to Meet the Demands of Low The Promise of More Efficient Power Production According to the International Energy Agency, modern coalfired power plants across the world average 33 percent efficiencyHow Coal Plants Can Increase Efficiency and Cut Emissions

High Efficiency Low Emission Coal HELE WCA

Moving the current average global efficiency rate of coalfired power plants from 375% to 475% by deploying more advanced offtheshelf technology could cut two gigatonnes of CO2 emissions Deploying high efficiency, low emission (HELE) coalfired power plants is a key first step along a pathway to nearzero emissions from coal with carbon capture, use and storage (CCUS) HELE technologies