عنا

مرحبا هل يمكنني مساعدتك؟

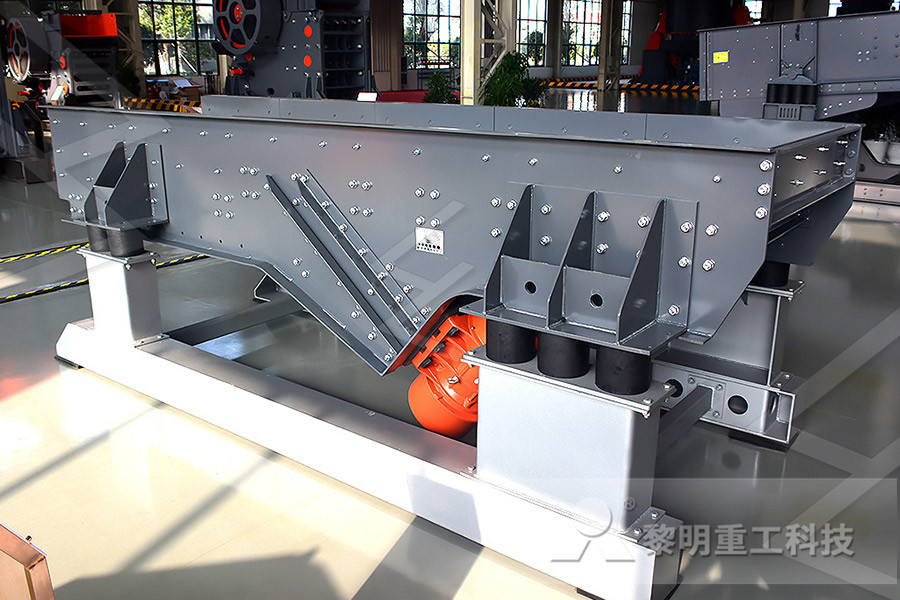

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

process of creating slurry of tailings

process of creating slurry of tailings

The Mount Polley tailings spill occurred in the Cariboo region of central British Columbia, CanadaThe spill began 4 August 2014 with a breach of the Imperial Metalsowned Mount Polley copper, gold and silver mine tailings pond, releasing its water and slurry with years worth of mining waste into Polley LakeThe spill flooded Polley Lake, creating a plug at Hazeltine Creek, and continued into Slurry pipelines are commonly used to transfer mine residue from the processing plant to the tailings storage facility Historically these pipelines were designed to operate at low solids concentrations, however as dewatering technology improved and solids concentrations increased, residue disposal systems have become significantly more complexTailings Paterson CookeThey are typically created as mined ore is crushed, ground and processed to separate the valuable minerals and create a saleable concentrate product The waste from this process is called tailings Due to the nature of the ore separation processes, tailings are commonly in the form of a slurry of fine mineral particles and waterTailings Management Teck

process of creating slurry of tailings

and processed to separate the valuable minerals and create a saleable concentrate product The waste from this process is called tailings Due to the nature of the ore separation processes, tailings are commonly in the form of a slurry of fine mineral particles and water Management of tailings Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Tailings Dry Stacking Process Xinhai In the early days of the tailings dry discharge technology, full tail concentrationpressure filtration (filtration) is the main processAlthough this process has obvious advantages over traditional tailings storage, a large number of problems have been found in the application process, including high onetime investment, high operating cost and large floor areaTailings Disposal Methods and Equipments MC

Tailings Management Teck

Tailings are a common byproduct of the mining process They are typically created as mined ore is crushed, ground and processed to separate the valuable minerals and create a saleable concentrate product The waste from this process is called tailings Due to the nature of the ore separation processes, tailings are commonly in the form of a slurry of fine mineral particles and water Tailings is a common byproduct of the mineral recovery process They usually take the form of a liquid slurry made of fine mineral particles – created when mined ore is crushed, ground and processed – and water Focus areas About tailings Tailings is a common byproduct of the mineral recovery process, usually comprising a liquid slurry of fine mineral particles and water Global ICMM TailingsThe modern tailings designer has a range of tailings products to choose from depending upon how much water is removed from the slurry prior to discharge The removal of water not only can create a better storage system in some cases (eg dry stacking, see below) but can also assist in water recovery which is a major issue as many mines are in arid regions In a 1994 description of tailings Tailings Wikipedia

Tailings Centrifuge Canada’s Oil Sands Innovation

The centrifuge technology process consists of three steps The FFT is d from the tailings pond A polymer (the same kind that is used at a municipal water treatment plant) is added to the FFT slurry The slurry is then fed into a centrifuge that spins the water out and produces a clay material that has the consistency of a mud cakeGold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Tailings Dry Stacking Process XinhaiUnderstanding and modelling of the thickening process has been at the heart of research projects by the CSIRO and other international entities for the past 50 years, with significant progress being made over the past 20 years Thickener designs have evolved to allow for compression of the settled slurry in the thickener by deepening and steepening thickener cones, and rake designs that promote Mill tailings management – high density thickened slurries

Tailing Disposal an overview ScienceDirect Topics

The predominant method of tailings disposal is by pumping and subaerial deposition of an aqueous slurry (typically at 30–45% initial solids concentration by mass and an initial gravimetric moisture content, w, of 233–122%) to a surface TSF The tailings may be discharged from a single pipe outlet or from a number of reduced diameter spigots off the main perimeter pipeline Following Example Application of Slurry Rheology for a Tailings Pipeline An iron ore processing plant located in the Pilbara Region of Western Australia was undergoing a raise in the wall height for the storage facility to increase the long term capacity A series of slurry rheology tests had been conducted and a relationship of slurry shear rate and shear stress values were determined The data was Slurry rheology and tailings pumping design Pump The resulting slurry is pumped to the froth production plant, where a bitumenrich froth is recovered The balance of the oil sands slurry is processed in dewatering equipment, which separates the slurry into warm water that is recycled in the plant and into hydrocyclone underflow (coarse sand tailings) and thickener underflow (thickened tailings [TT]) The bitumenrich froth is deaerated Section 5: Process Alberta

Tailings Retreatment: The Next Revenue Source for the

Tailings deposited into dams are in the form of a slurry In 1998, a tailings dam failed at the Los Frailes zinc mine in Spain, causing more than one billion gallons of acidic, heavy metalladen sludge to spill into the surrounding area, eventually making its way into the Guadiamar River The spill decimated the area, resulting in massive wildlife dieoffs, water and soil contamination, and Understanding and modelling of the thickening process has been at the heart of research projects by the CSIRO and other international entities for the past 50 years, with significant progress being made over the past 20 years Thickener designs have evolved to allow for compression of the settled slurry in the thickener by deepening and steepening thickener cones, and rake designs that promote Mill tailings management – high density thickened slurries Example Application of Slurry Rheology for a Tailings Pipeline An iron ore processing plant located in the Pilbara Region of Western Australia was undergoing a raise in the wall height for the storage facility to increase the long term capacity A series of slurry rheology tests had been conducted and a relationship of slurry shear rate and shear stress values were determined The data was Slurry rheology and tailings pumping design Pump

Tailings Centrifuge Canada’s Oil Sands Innovation

The centrifuge technology process consists of three steps The FFT is d from the tailings pond A polymer (the same kind that is used at a municipal water treatment plant) is added to the FFT slurry The slurry is then fed into a centrifuge that spins the water out and produces a clay material that has the consistency of a mud cakeGold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Tailings Dry Stacking Process XinhaiT1 THICKENED SLURRY DISPOSAL METHOD FOR PROCESS TAILINGS AU Palmer, Bertrand AU Krizek, Raymond John PY 1987/1/1 Y1 1987/1/1 N2 Common practice in the disposal of process tailings consists of impounding the wastes as thin slurries or suspensions in diked containment areas Such a procedure poses problems relating to the low strength of the residue, possible failure of THICKENED SLURRY DISPOSAL METHOD FOR PROCESS TAILINGS

About Tailings – Global Tailings Review

Tailings is a common byproduct of the process of extracting valuable minerals and metals from mined ore They usually take the form of a liquid slurry made of fine mineral particles, created as mined ore is crushed, ground and processed Effective tailings management is integral to the safe and sustainable production of metals and minerals Tailings can be stored in a variety of ways: which The Inline Dewatering Process uses the concept of cross flow filtration (CFF) whereby a slurry of tailings, flowing through a special pipe, is dewatered Filtrate (primarily water) is released through the pipe wall while most of the mineral solids are retained Some of the solids are deposited along the inside wall of the pipe, forming a filter cake The filter cake remains porous with Inline Dewatering of Oil Sands Tailings Natural Historically, the only option for tailings storage was to deal with a tailings slurry Tailings were disposed of in the most convenient manner, such as in rivers and streams By about 1930, this type of tailings disposal was stopped in the western world, creating the first benchmark regulations on mine waste management In a few areas of the world, tailings are still disposed of in waterways History of Tailings Dam Design Klohn Crippen BergerKlohn

Section 5: Process Alberta

The resulting slurry is pumped to the froth production plant, where a bitumenrich froth is recovered The balance of the oil sands slurry is processed in dewatering equipment, which separates the slurry into warm water that is recycled in the plant and into hydrocyclone underflow (coarse sand tailings) and thickener underflow (thickened tailings [TT]) The bitumenrich froth is deaerated Tailings deposited into dams are in the form of a slurry In 1998, a tailings dam failed at the Los Frailes zinc mine in Spain, causing more than one billion gallons of acidic, heavy metalladen sludge to spill into the surrounding area, eventually making its way into the Guadiamar River The spill decimated the area, resulting in massive wildlife dieoffs, water and soil contamination, and Tailings Retreatment: The Next Revenue Source for the