عنا

مرحبا هل يمكنني مساعدتك؟

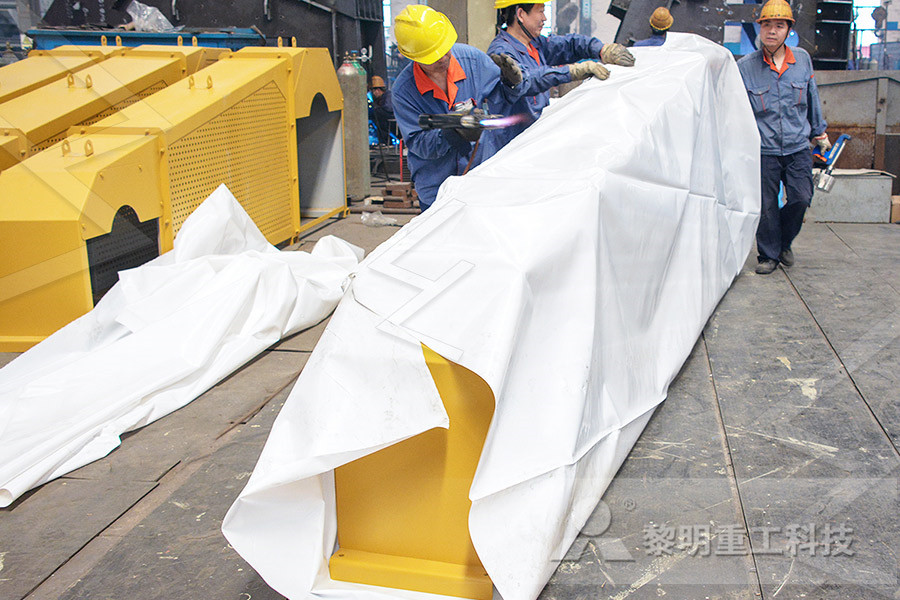

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

iron ore vertical pelletizing technology

Iron Ore Pelletizing Process: An Overview IntechOpen

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the pelletizing Pelletizing is a process which involves mixing of very finely ground particles of iron ore fines having a size which is less than 200 mesh (0074 mm) with additives like bentonite and then shaping them into near oval/spherical balls having size in the range of 8 mm to 16 mm in diameter by a pelletizer and hardening the balls by firing with a fuelIntroduction to Iron ore Pellets and Pelletizing processes This chapter aims to provide an overview and the evolution of iron ore pelletizing process including: Pelletizing process and raw materials Balling technologies Bonding mechanisms Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2Iron Ore Pelletizing Process: An Overview

Iron ore pelletizing systems

Iron ore pelletizing systems Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make steel is supplier of both Straight Grate and Grate Kiln pellet plants Features is the only supplier in the world that has both the Straight Grate and the Outotec has signed a contract with Beijing Shougang International Engineering Technology Co Ltd on the delivery of new environmentally sound technology for ’s (Zhong Tian) iron ore pelletizing plant to be built in Nantong, China The order value is not disclosed The contract has been booked into Outotec’s Q3 2020 orders received Outotec wins order for a large iron ore pelletizing Learn about Outotec's Traveling Grate Pelletizing Plant the industry's leading induration technology for iron ore pellet productionIntroduction to Outotec Pelletizing Technology YouTube

Iron Ore Pellet an overview ScienceDirect Topics

122213 Pelletizing Technologies There are two main types of pelletizer that are used to produce iron ore pellets at industrial scale, the rotary drum and the disc Besides iron ore agglomeration, these pelletizers can also be used for other materials such as copper ore, gold ore, coal, and fertilizer [12 ]Sintering and Pelletizing Outotec Outotec Traveling Grate Sintering is suitable for sintering a wide range of raw materials, including iron, manganese and ferronickel, while Outotec Traveling Grate Pelletizing is the industry's leading induration technology for iron ore pellet production which is designed for a wide range of plant capacities and produces uniform pellets with excellent iron ore vertical pelletizing technology Outotec has signed a contract with Beijing Shougang International Engineering Technology Co Ltd on the delivery of new environmentally sound technology for ’s Zhong Tian iron ore Outotec Wins Order for Large Iron Ore Pelletizing

The Iron Pelletizing Process: Part One :: Total Materia

The most commonly employed agglomeration technique is pelletizing by which a mixture of iron ore, water, and binder is rolled up in a mechanical disc or drum to produce agglomerates (green or wet pellets) Figure 1: Iron pellets The pelletizing process is a process which contains numerous subprocesses, or process segments On the way from the mine to a final product, the iron ore goes Iron ore pelletizing systems Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make steel is supplier of both Straight Grate and Grate Kiln pellet plantsIron ore pelletizing systems 122213 Pelletizing Technologies There are two main types of pelletizer that are used to produce iron ore pellets at industrial scale, the rotary drum and the disc Besides iron ore agglomeration, these pelletizers can also be used for other materials such as copper ore, gold ore, coal, and fertilizer [12 ]Iron Ore Pellet an overview ScienceDirect Topics

Outotec wins order for a large iron ore pelletizing

Outotec has signed a contract with Beijing Shougang International Engineering Technology Co Ltd on the delivery of new environmentally sound technology for ’s (Zhong Tian) iron ore pelletizing plant to be built in Nantong, China The order value is not disclosed The contract has been booked into Outotec’s Q3 2020 orders receivedPelletizing of iron ore concentrates in pelletizing discs leads to narrow grain size distributed pellets with smooth surface Pelletizing – how? The process chamber of a pelletizing disc is made by an inclined, rotating, flat cylindrical pan Due to rotation of the pan, the fine material is pulled along to the disc uppermost point and then rolling down onto a material bed Caused by the Iron ore pelletizing technology Mineral Processing verticalshaftkilns for firing the pellets Plant capacities were between 10,000 and 60,000 tons/ year [1] The world installed pelletizing capacity is currently estimated to be 4807 million (PDF) Iron Ore Pelletizing Process: An Overview

Sintering and Pelletizing Outotec

Our innovative sintering and pelletizing solutions are based on over 60 years’ experience and worldclass RD Outotec Traveling Grate Sintering is suitable for sintering a wide range of raw materials, including iron, manganese and ferronickel, while Outotec Traveling Grate Pelletizing is the industry’s leading induration technology for iron ore pellet production which is designed for a Sintering and Pelletizing Outotec Outotec Traveling Grate Sintering is suitable for sintering a wide range of raw materials, including iron, manganese and ferronickel, while Outotec Traveling Grate Pelletizing is the industry's leading induration technology for iron ore pellet production which is designed for a wide range of plant capacities and produces uniform pellets with excellent iron ore vertical pelletizing technologyBy means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses, cars and household appliances Iron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with Iron ore pellets and Pelletizing processes Vale

Beneficiation Plants and Pelletizing Plants for Utilizing

The plants are usually built in the vicinity of a mine, or near the ore shipping port; however, as in the case of Kobe Steel's Kakogawa works, a pelletizing plant is often built in steelworks The granulation is done by a balling disc or by a balling drumSintered ore is made by partially melting and sintering coarse iron ore 1 to 3mm in size into products having a size of 15 to 30mm The sintering process uses the combustion heat of coke breeze (fuel) Pellets are made from iron ore that is finer than that used for sintered oreKOBELCO Pelletizing ProcessIron ore is primarily found as the oxides of iron, notably hematite and magnetite and as hydroxides like goethite and limonite Small amounts are found as the carbonates in siderite, as sulphides (PDF) Iron Ore Pelletization Technology and its

Outotec wins order for a large iron ore pelletizing

Outotec has signed a contract with Beijing Shougang International Engineering Technology Co Ltd on the delivery of new environmentally sound technology for ’s (Zhong Tian) iron ore pelletizing plant to be built in Nantong, China The order value is not disclosed The contract has been booked into Outotec’s Q3 2020 orders receivedPelletizing of iron ore concentrates in pelletizing discs leads to narrow grain size distributed pellets with smooth surface Pelletizing – how? The process chamber of a pelletizing disc is made by an inclined, rotating, flat cylindrical pan Due to rotation of the pan, the fine material is pulled along to the disc uppermost point and then rolling down onto a material bed Caused by the Iron ore pelletizing technology Mineral ProcessingBy means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses, cars and household appliances Iron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with Iron ore pellets and Pelletizing processes Vale

iron ore vertical pelletizing technology

Sintering and Pelletizing Outotec Outotec Traveling Grate Sintering is suitable for sintering a wide range of raw materials, including iron, manganese and ferronickel, while Outotec Traveling Grate Pelletizing is the industry's leading induration technology for iron ore pellet production which is designed for a wide range of plant capacities and produces uniform pellets with excellent An attempt is made to present a logical account of ironore pelletizing operations (balling and hardening) with particu lar reference to laboratory techniques The factors leading to the growth of the industry are dealt with historically, con cluding with an examination of pellets as a blast furnace feedPelletizing EPrintsThe plants are usually built in the vicinity of a mine, or near the ore shipping port; however, as in the case of Kobe Steel's Kakogawa works, a pelletizing plant is often built in steelworks The granulation is done by a balling disc or by a balling drumBeneficiation Plants and Pelletizing Plants for Utilizing

KOBELCO Pelletizing Process

Sintered ore is made by partially melting and sintering coarse iron ore 1 to 3mm in size into products having a size of 15 to 30mm The sintering process uses the combustion heat of coke breeze (fuel) Pellets are made from iron ore that is finer than that used for sintered ore The plant, which will be the fifth large iron ore pelletizing plant delivered by Outotec in China, is based on our environmentally sound traveling grate technology,” says Tobias Stefan, Vice President, Ferrous Heat Transfer business line at Outotec Pellet production at the Zhong Tian plant is estimated to start by the end of 2021 Outotec wins order for a large iron ore pelletizing Circular Pelletizing Technology The everhigher portion of fine and ultrafine iron ore from mining sites means that the pelletizing process is becoming more important for ore agglomeration This has led to an increased interest by steel producers to invest in their own pellet plants to become independent of changing prices for pellets on the World´s first Circular Pelletizing Plant from Primetals