عنا

مرحبا هل يمكنني مساعدتك؟

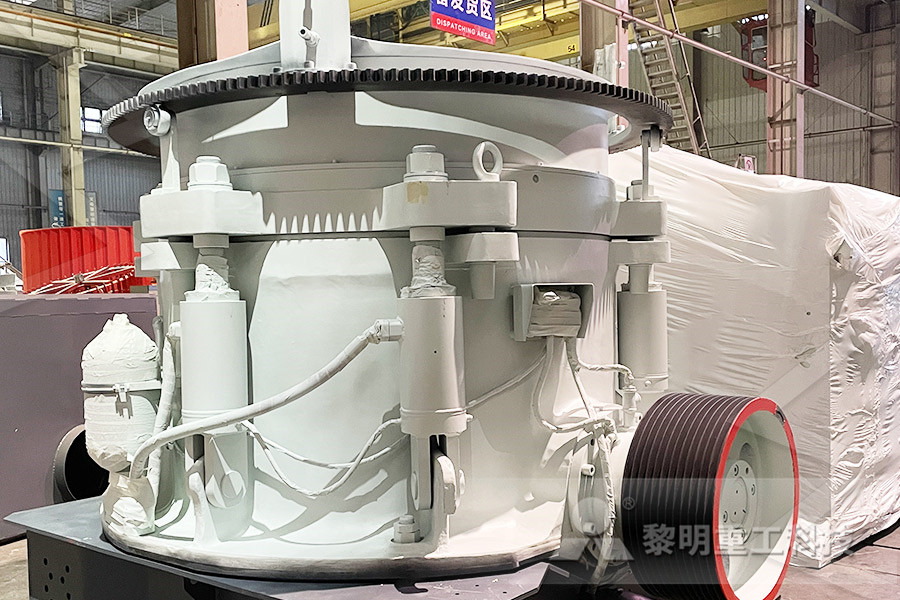

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

refining low grade iron ore beneficiation

Iron Ore Beneficiation Process

During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being silica and moisture The general processes to which low grade iron ores are amenable Processes based on the gravity separation technique are extensively being used in iron ore beneficiation because of their lowcost, ease of operation, and ecofriendly nature The gravity concentration techniques are based on the differential settling velocities of the different particles constituting the ore The settling velocity of particles is governed jointly by weight (volume and Low grade Iron Ore Beneficiation and the Process of These ores can be directly used in the production of iron and steel All other ores need beneficiation and certain processing before they are used in the production of iron and steel Low grade iron ores cannot be used as such for the production of iron and steel and need to be upgraded to reduce its gangue content and increase its Fe content The process adopted to upgrade the Fe content of iron ore Beneficiation of Iron Ores – IspatGuru

Refining Low Grade Iron Ore Beneficiation

Refining Low Grade Iron Ore Beneficiation nickel ore processingickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely differentoppernickel sulfide ore beneficiation methods, the most important is the flotation, magnetic and reelection is usually secondary dressing methodBeneficiation of a lowgrade iron ore was investigated by combination of the lowintensity magnetic separation and reverse flotation methods The main constituents of the representative sample were 3686% Fe, 81% FeO, 142% CaO, 136% SiO 2, and 012% S based on the Xray fluorescence, titration, and Leco analysis methods The mineralogical studies by the Xray diffraction, scanning Beneficiation of a lowgrade iron ore by combination of Refining Low Grade Iron Ore Beneficiation Aug 16 2019 the remaining iron ore mines in china are mostly lowgrade mines that produce ores with only 20 to30 iron content at the same time chinas demand for steel remains robust if chinese iron ore supplies remain constrained then prices could rise on Chat Online Hydraulic Cone Crusher Hydraulic cone crusher is also known as hydro cone crusher Refining Low Grade Iron Ore Beneficiation PANOLA Mining

process to refine low grade ores increase iron content

Effective Beneficiation of Low Grade Iron Ore Through Jigging lower grade lumps and fines are increasing day by day due to increase in the Lot of developments in chat online ; process to refine low grade ores increase iron content process to refine low grade ores increase iron content BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by , chat online We have Chinese Low Grade Iron Ore Beneficiation,Beneficiation laterite iron ore with fe content 5627, sio 2 319, al 2 o 3 632 and tio 2 079 this research use washing process with ordinary equipment like log washer, wet vibrating screen and rotary drum washer result have improvement fe content to 60Refining Low Grade Iron Ore BeneficiationIron Ore Beneficiation ioresearchhubnewcastleeduau Iron Ore Beneficiation Introduction Iron Ore Beneficiation increases the grade of iron whilst maximising recovery and reduces the content of ultrafine low grade slimes to maximise return on investment from the mining process prior to sale or further refining in the iron making processrefining low grade iron ore beneficiation MC World

Refining Low Grade Iron Ore Beneficiation

Refining Low Grade Iron Ore Beneficiation nickel ore processingickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely differentoppernickel sulfide ore beneficiation methods, the most important is the flotation, magnetic and reelection is usually secondary dressing methodWe have Chinese Low Grade Iron Ore Beneficiation,Beneficiation laterite iron ore with fe content 5627, sio 2 319, al 2 o 3 632 and tio 2 079 this research use washing process with ordinary equipment like log washer, wet vibrating screen and rotary drum washer result have improvement fe content to 60 for magnetic iron ore low grade with fe content 3886, beneficiation is done withBeneficiation Process Of Low Grade Fe Iron OreLow Grade Iron Ore Beneficiation In the past 50 years, due to high demand and intensive mining operations, the high grade deposits are depleting fast By 20192020 it is estimated that the relatively low grade reserves are to be tapped The importance of tailings can be understood by this proverb common to all mineral engineers “Today’s tailing is tomorrow’s ore” New technologies must Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

Beneficiation of a lowgrade iron ore by combination of

Beneficiation of a lowgrade iron ore was investigated by combination of the lowintensity magnetic separation and reverse flotation methods The main constituents of the representative sample were 3686% Fe, 81% FeO, 142% CaO, 136% SiO 2, and 012% S based on the Xray fluorescence, titration, and Leco analysis methods The mineralogical studies by the Xray diffraction, scanning However, these ores have been largely depleted, and iron is now produced from lowgrade ores that are treated to improve their quality; this process is called beneficiation Iron ores are refined in the blast furnace The product of the blast furnace is called pig iron and contains about 4% carbon and small amounts of manganese, silicon, phosphorus, and sulfur About 95% of this iron is Iron (Element): Production and Refining InfopleaseEffective Beneficiation of Low Grade Iron Ore Through Jigging lower grade lumps and fines are increasing day by day due to increase in the Lot of developments in chat online ; process to refine low grade ores increase iron content process to refine low grade ores increase iron content BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by , chat online process to refine low grade ores increase iron content

Beneficiation Low Grade Iron Ore Fines

Refining Low Grade Iron Ore Beneficiation Experimental study on the beneficiation of lowgrade iron ore fines using hydrocyclone desliming, reduction roasting and Get Price Technology For Beneficiation Of Low Grade Iron Ore Fines mining technology: beneficiation of Low grade iron ore fines May 05, 2009 Technology has been engaged in Iron ore research for the beneficiation of Iron Metallurgical ContentThe Iron Ore Process FlowsheetCRUSHING AND GRINDINGHYDROCLASSIFICATION AND MAGNETIC FINISHINGCONDITIONING AND FLOTATIONSILICA FLOTATION REAGENTSTHICKENING AND FILTERINGADVANTAGES OF FLOTATION Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron Beneficiation of Iron Ore Mineral Processing MetallurgyLowgrade hematite ores need to be upgraded to achieve the required iron content, which involves more complicated ore beneficiation processes The level of comminution required for the lowgrade hematite ore is similar to highgrade ores to deliver the same products, lumps and fines In most cases, the fines product requires additional separation/desliming stages to remove fines containing a Ore Beneficiation an overview ScienceDirect Topics

Iron Ore Processing for the Blast Furnace

The process of mining low grade iron ore, or taconite, requires massive resources Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required The equipment used includes diamond bit rotary drills, hydraulic shovels and loaders, water wagons, production trucks and heavyduty conveyors National Steel Pellet Company’s plant is capable of producing 535 Beneficiation of −2 mm lowgrade iron ore tailings (507%Fe, 108%SiO 2 and 44%Al 2 O 3) from Western Australia was studied The sample consisted of hydrohaematite, goethite and quartz, with lesser kaolinite and shale Two processing options were tested, which were wet highintensity magnetic separation (WHIMS), either using deslimed or untreated feed, and reduction (magnetising Experimental study on the beneficiation of lowgrade iron Beneficiation of a lowgrade iron ore was investigated by combination of the lowintensity magnetic separation and reverse flotation methods The main constituents of the representative sample were 3686% Fe, 81% FeO, 142% CaO, 136% SiO 2, and 012% S based on the Xray fluorescence, titration, and Leco analysis methods The mineralogical studies by the Xray diffraction, scanning Beneficiation of a lowgrade iron ore by combination of

Beneficiation of Low Grade Iron Ore with Manganese Content

Beneficiation of Low Grade Iron Ore with Manganese Content as Raw Material for Ferro Kusno Isnugroho*, David Candra Birawidha Mineral Processing Division– Indonesian Institute of Science (LIPI) kojay99@yahoo, cbr500@yahoo Abstract Iron ore beneficiation process research mostly examines iron ore with laterite type, magnetic type or hematite type In Lampung provinces, there is We have Chinese Low Grade Iron Ore Beneficiation,Beneficiation laterite iron ore with fe content 5627, sio 2 319, al 2 o 3 632 and tio 2 079 this research use washing process with ordinary equipment like log washer, wet vibrating screen and rotary drum washer result have improvement fe content to 60 for magnetic iron ore low grade with fe content 3886, beneficiation is done withBeneficiation Process Of Low Grade Fe Iron OreLow Grade Iron Ore Beneficiation In the past 50 years, due to high demand and intensive mining operations, the high grade deposits are depleting fast By 20192020 it is estimated that the relatively low grade reserves are to be tapped The importance of tailings can be understood by this proverb common to all mineral engineers “Today’s tailing is tomorrow’s ore” New technologies must Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

ISSUES RELATING TO CHARACTERIZATION AND BENEFICIATION

AND BENEFICIATION OF LOW GRADE IRON ORE FINES BK Mishra, PSR Reddy, B Das, SK Biswal, S Prakash, S K Das Institute of Minerals Materials Technology Table1 Mineralogical variations of the iron ore samples Table2 Quantitative mineralogy and liberation of typical hematite sample 32 Chemical characteristics of the sample The complete chemical analysis of different May 09 2020 Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting which involves melting the ore to remove the metal contentThe process of iron ore beneficiation has two complementary goals and these define the methods used to refine it The iron content of the ore needs to be increased and gangue which is native rock and iron ore beneficiation plant required how much waterBeneficiation Of Iron Ore Beneficiation of iron oreeneficiation of iron ore,during the last ten years great strides have been made on the mesabi range in the practice of beneficiating low grade iron ore material by beneficiation is meant all methods of removing impurities and raising the iron content to a point where it can be sold in open market the principal impurities being silica and Methods Of Beneficiation Of Low Grade Iron Ores

iron ore beneficiation mining techniques animation

A Beneficiation Study on a Low Grade Iron Ore by Gravity and Know More 25 Aug 2018 In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies Iron Ore Beneficiation Know More Iron Ore beneficiation solutions from Multotec are designed so that each stage of the mineral beneficiation process, from ROM stockpiles characterization and processing of low Know More 19 May 2008 Detailed characterization followed by beneficiation of lowgrade iron ore slime from Jilling The work involved separating the gangue minerals viz quartz and A simple flowsheet has been suggested to improve the yieldwhat is beneficiation of iron ore flowchart