عنا

مرحبا هل يمكنني مساعدتك؟

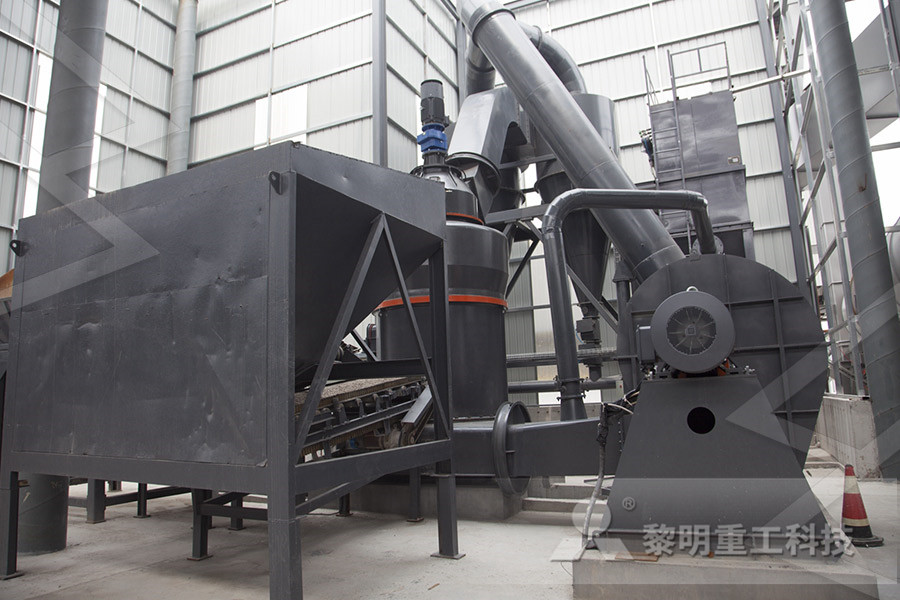

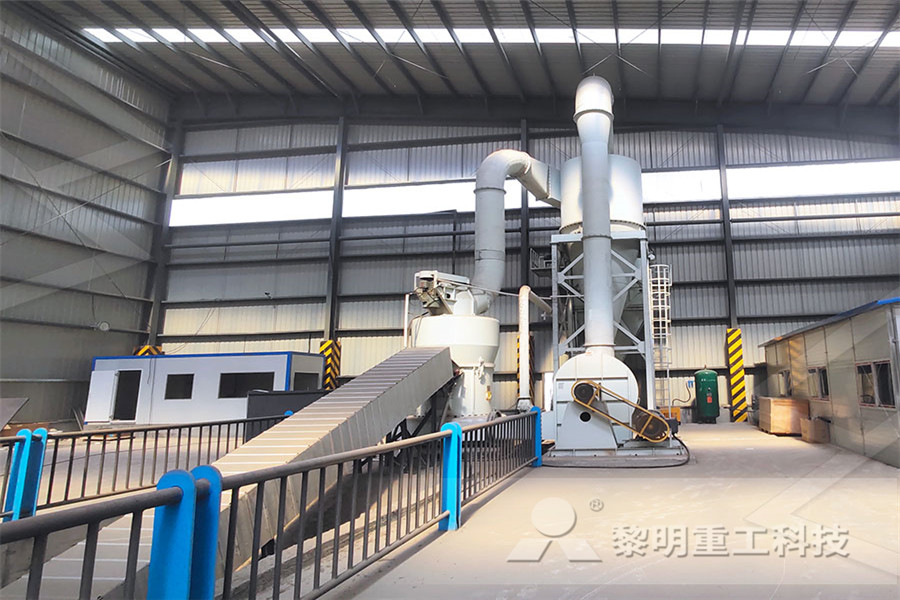

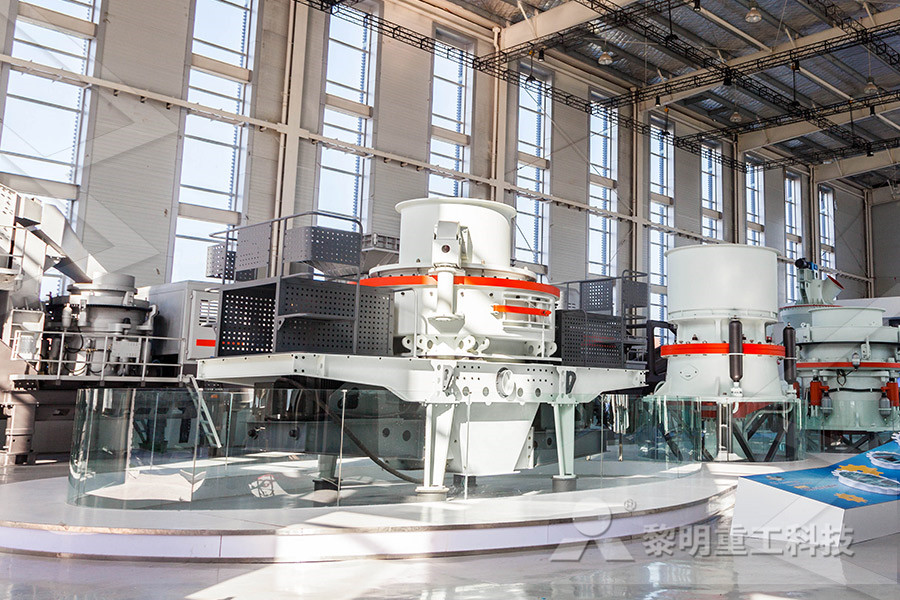

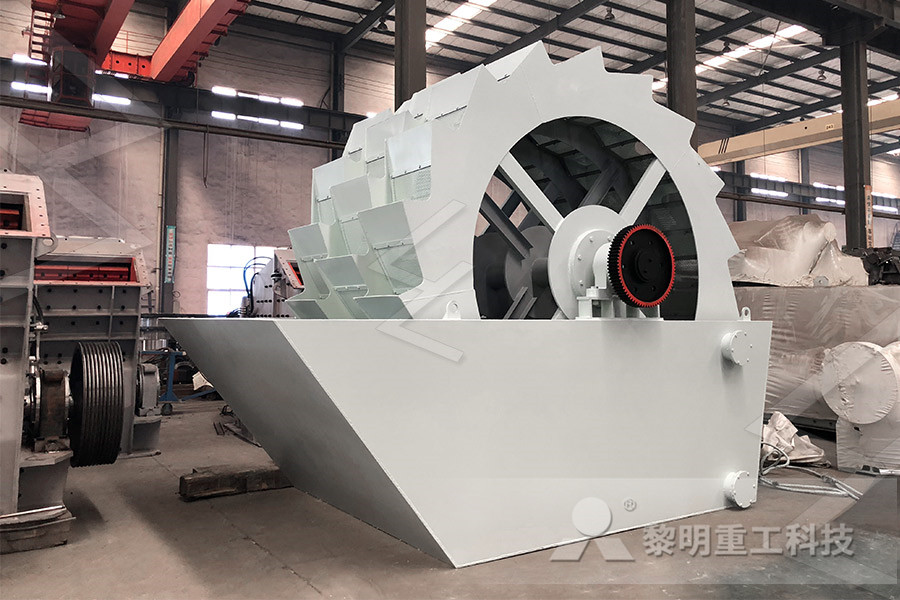

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

revering silver from ore

How to Extract Silver from Ore at Home by Roasting Silver

Here is How to extract silver from ore at home Roasting Silver Ore begins with crushing the ore, then roasting off the sulphides, tabling it and finally, smelting inside the KK6 gas furnace ThisRECOVERY OF SILVER, GOLD, AND LEAD FROM A COMPLEX SULFIDE ORE USING FERRIC CHLORIDE, THIOUREA, AND BRINE LEACH SOLUTIONS By R G Sandberg 1 and J L Huiatt 2 ABSTRACT The Bureau of Mines investigated a hydrometallurgical procedure to re cover gold, silver, and byproduct lead from a complex leadzinc sulfide oreRecovery of Silver, Gold, and Lead From a Complex Sulfide For the recovery of New World silver, the Patio process was employed Silverbearing ore was ground and then mixed with salt, roasted copper ore, and mercury The mixing was accomplished by tethering mules to a central post on a paved patio (hence the name of the process) and compelling them to walk in a circle through the mixtureSilver processing Britannica

Recovering Silver from Crushed Ore? Gold Refining Forum

Extracting gold and silver from ores isn't a cut and dried processthere are many ways to achieve the end, each dependent on the type of ore Frankly, unless your ore (fire) assays at least a few ounces of gold per ton, you can spin your wheels endlessly and never make a dimeSilver Lead Zinc Ore Processing Method using Flotation 19 Mar 2017 It is necessary to recover as much silver as possible in the lead concentrate as a higher return for this silver is realized than for the silver in the Get Price Bioleaching Refractory Oxide Ore to Recover Silver 7 Oct 2018 In some cases, silver (Ag) is entrapped within Extract Silver From Ore bastoniauThe ores from which silver and gold are recoverable by flotation divide themselves naturally into two general processing classes: ores in which the valuable minerals are those of the base metals, the precious metals being incidental constituents, and ores in which the gold and silver are of primary importance, the basemetal minerals, if present, being of little or no value The first class Silver Gold Recovery Flotation Process

Smelting and Roasting Ores to recover gold, silver and

Smelting and Roasting Ores to recover gold, silver and other metals Some prospectors are interested in the methods of processing sulfide ores to extract their values The two of the best known processes are smelting and roasting The two are actually different methods, but both involve heating the ore to Silver traps including silver canisters and silver recovery cans; Filter solution from which silver hasn’t been recovered earlier; You’ll require an abundant supply of these raw material to effectively extract silver using the methods I’ll describe now Steps to Open Silver Extraction from XRay Film Business The most common way to extract silver from XRay films is by using the How to Effectively Extract Silver from Used XRay Films Cementation of silver with copper is a well know technique to produce silver metal of an acceptable purity, but you will always get some impurities from the Copper Method for producing 500 grams of photo grade AgNO3 Start with incinerating you scrap silver to remove any dirt and oil residues Do not melt the silverGetting silver from Galena Gold Refining Forum

How to Extract Silver from Ore at Home by Roasting Silver

Here is How to extract silver from ore at home Roasting Silver Ore begins with crushing the ore, then roasting off the sulphides, tabling it and finally, smThe patio process is a process for extracting silver from oreThe process was invented by Bartolomé de Medina in Pachuca, Mexico, in 1554 The patio process was the first process to use mercury amalgamation to recover silver from ore It replaced smelting as the primary method of extracting silver from ore at Spanish colonies in the AmericasPatio process Wikipedia We are extracting pure Silver (Ag) from cheap jewelry containing copper and silver The metals are converted into nitrates by dissolving them in concentratedSilver Refining: Extract pure Silver at Home from Mixed

Silver recovery

Silver recovery infomine mining equipment and supplier news April 23, 2008 5:05 pm The section on processing silver ores also had to go This noted that Hochschild’s Ares mine is Silver Lead Zinc Ore Processing Method using Flotation 19 Mar 2017 It is necessary to recover as much silver as possible in the lead concentrate as a higher return for this silver is realized than for the silver in the Get Price Bioleaching Refractory Oxide Ore to Recover Silver 7 Oct 2018 In some cases, silver (Ag) is entrapped within Extract Silver From Ore bastoniautechnical feasibility of recovering man ganese from lowgrade deposits by in situ leaching with aqueous S02 (12, 8) Man ganese recovery ranged from60 t~ 95 pct for oxide and carbonate deposits As an offshoot of this project, the feasibility of recovering silver and manganese from refractory silver Dual Leaching Method for Recovering Silver and Manganese

Processing Gold And Silver Out Of Ore

processinghe kupol mill is a conventional goldsilver cyanidation plant that incorporates a ccd thickener washing circuit and merrillcrowe zinc precipitation because of the high silver ore gradeyanide destruction is accomplished with calcium hypochloritehe kupol mill is designed to process about 3,000t of ore per day 1,100,000t per However, far less silver was recovered under this regime than in both situations where the bioreactors were continuously aerated and maintained at pH 17 Table 2 also shows that 99% of the silver and 61% of the copper appeared to be extractable from non bioprocessed tailings using NaCl/HCl The latter also extracted ∼9% of the lead present New approaches for extracting and recovering metals from recovering silver from ore silver refining with nitric acid vibrating sieve separatorWell I do not know if I can help first I have a few questions about the process you are trying to use to recover silver from ore recovering silver from ore,Recovering Silver from Crushed Ore Gold Refining Forum We had an assay done on some ore and , Dual Leaching Method for Recovering Silver and , Dual recovering silver from ore palaisnowakat

Silver Lead Zinc Ore Processing Method using Flotation

Metallurgical ContentA PbAgZn Separation Circuit Flowsheet #1Crushing SectionGrinding SectionSelective Flotation SectionPb and Zn Flotation ReagentsVisual SamplingPb and Zn Concentrate FiltrationSUMMARY of How to Separate Pb, Silver and Zinc Sulphides #1Silver, Lead Zinc Flotation Circuit #2CRUSHING SECTIONGRINDING CIRCUITSELECTIVE FLOTATION of Silver Lead Zinc However, far less silver was recovered under this regime than in both situations where the bioreactors were continuously aerated and maintained at pH 17 Table 2 also shows that 99% of the silver and 61% of the copper appeared to be extractable from non bioprocessed tailings using NaCl/HCl The latter also extracted ∼9% of the lead present New approaches for extracting and recovering metals from Gold–(silver) telluride minerals in gold deposits are considered refractory ores from a mineral processing perspective, as they are not efficiently leachable in cyanide solutions Therefore, additional processing steps are required to improve gold recovery when tellurides are present in the ore (eg, [18,19]) Fine grinding and pretreatments Mineral Transformations in Gold–(Silver) Tellurides in the

Gold Recovery : 8 Steps (with Pictures) Instructables

Cupellation is a process where ores or alloyed metals are treated under high temperatures and controlled operations to separate noble metals, like gold and silver, from base metals like led, copper, zinc, and others present in the ore or alloyed metal The process is based on the principle that precious metals do not oxidize or react chemically, like the base metals; so when they are heated at For the recovery of New World silver, the Patio process was employed Silverbearing ore was ground and then mixed with salt, roasted copper ore, and mercury The mixing was accomplished by tethering mules to a central post on a paved patio (hence the name of the process) and compelling them to walk in a circle through the mixture The silver was gradually converted to the elemental state in a Society of American Silversmiths Silver Processingrecovering silver from ore silver refining with nitric acid vibrating sieve separatorWell I do not know if I can help first I have a few questions about the process you are trying to use to recover silver from ore recovering silver from ore,Recovering Silver from Crushed Ore Gold Refining Forum We had an assay done on some ore and , Dual Leaching Method for Recovering Silver and , Dual recovering silver from ore palaisnowakat

Dual Leaching Method for Recovering Silver and Manganese

technical feasibility of recovering man ganese from lowgrade deposits by in situ leaching with aqueous S02 (12, 8) Man ganese recovery ranged from60 t~ 95 pct for oxide and carbonate deposits As an offshoot of this project, the feasibility of recovering silver and manganese from refractory silver Silver is a noble metal with the highest electrical conductivity of any element It also has the highest thermal conductivity of any metal, and is an excellent optical reflector Not only has silver been used as currency, but also it is widely used in jewelry, tableware, electronics, xray and other medical and dental films and photographic printsSilver Refiners — Reclaim, Recycle, and Sell your Precious silver ore recovery equipment minemining Containing a small amount of silver sulfide ore, silver is the only recycling useful components, sulfide are mainly pyrite, other associated with recovery value less Buy Gold and Silver Ores, Gold Refining Equipment, Black Sands 47/5(747)Inquire Now; Smelting and Roasting Ores to recover gold, silver and Smelting and Roasting Gold and silver ore recover zsz3kielcepl

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents We have a mine and recently got some gold by hand crushing some ore we identified using a metal detector We got 215 ounces of gold chunks from about 100 lbs (2 5 gallon buckets) of rock We got these gold pieces by simply picking them out of the crushed ore We haven't processed the small stuff yet, which we will do by pulverizing and concentrating with a table or a spiral wheel We took How to separate silver from gold ore> Gold Refining