عنا

مرحبا هل يمكنني مساعدتك؟

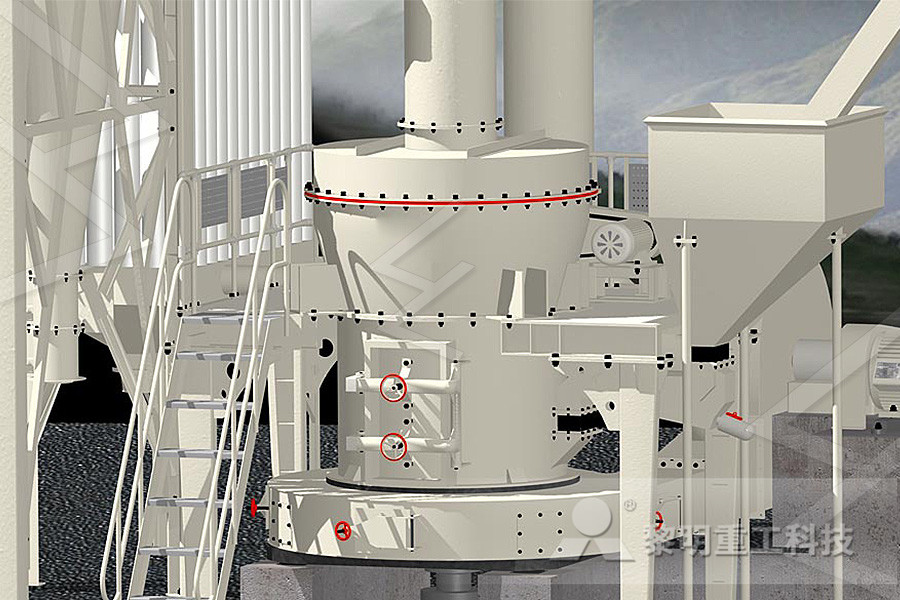

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

diagram of the process of cleaning equipment

Cleaning Pharmaceutical Equipment Dober

The cleaning process of a fluid bed dryer is largely determined by size of vessel, the residue needed to be cleaned, and the limitations of cleaning equipment Because of the vertical surfaces, the most common challenge for a fluid bed is getting the detergent solution to stick to the vertical walls and/or to maintain contact of solution to walls This can create the need for manual cleaning circulated through the equipment in a cleaning circuit There are two ways of performing CIP Either the cleaning detergents are put to drain immediately after they have been used This is called singleuse cleaning and is often used when the object is very dirty, such as a UHT plant The other alternative is when less dirty objects are cleaned, such as tanks or pipes that have cold surfaces HANDBOOK Cleaning in placeCleaning frequency must be clearly defined for each process line (ie, daily, after production runs, or more often if necessary) The type of cleaning required must also be identified The objective of cleaning and sanitizing food contact surfaces is to remove food (nutrients) that bacteria need to grow, and to kill those bacteria that are present It is important that the clean, sanitized Basic Elements of Equipment Cleaning and Sanitizing in

Basics on Processing Sterilization Sterile Materials

Equipment many types of cleaning equipment are available, the most commonly used are: Washer/decontaminator the washer/decontaminator is used to clean heattolerant items The cycle consists of several washes and rinses, followed by a steam sterilization cycle appropriate for the types of items contained in the load Although subjected to a cycle designed to sterilize clean items, items CIP systems offer fast, efficient and reliable cleaning of all types of process plant It's a method which cleans complete items of plant equipment or pipelines circuits without dismantling the equipment CIP systems are divided in differents operations : 1 Flushing in order to eliminate residues 2 Alkaline cleaning operation : alkaline detergents dissolve fat and proteins, and cleaning Cleaning in CIP processes Lenntechcleaning of the equipment in dairies has been done by workers who had to dismantle the equipment and enter the reservoir to reach the area they needed to clean up Products were often infected by inadequately cleaned equipment 2 The system of circular “cleaning in place” (CIP) which is adapted to the various parts of the production plant has been developed in order to achieve good results CIP Cleaning Processes in the Dairy Industry

Basics on Processing Sterilization Sterile Materials

Equipment many types of cleaning equipment are available, the most commonly used are: Washer/decontaminator the washer/decontaminator is used to clean heattolerant items The cycle consists of several washes and rinses, followed by a steam sterilization cycle appropriate for the types of items contained in the load Although subjected to a cycle designed to sterilize clean items, items cleaning of the equipment in dairies has been done by workers who had to dismantle the equipment and enter the reservoir to reach the area they needed to clean up Products were often infected by inadequately cleaned equipment 2 The system of circular “cleaning in place” (CIP) which is adapted to the various parts of the production plant has been developed in order to achieve good results CIP Cleaning Processes in the Dairy IndustryThe scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation A process flow diagram for a typical coal cleaning plant is presented in Figure 111011110 Coal Cleaning

Process Flowchart Draw Process Flow Diagrams by Starting

ConceptDraw is Professional business process mapping software for making process flow diagram, workflow diagram, general flowcharts and technical illustrations for business documents It is includes rich examples, templates, process flowchart symbols ConceptDraw flowchart maker allows you to easier create a process flowchart Use a variety of drawing tools, smart connectors, flowchart symbols Best Practice Guidelines for Cleaning, Disinfection and Sterilization in Health Authorities December 2011 Page 1 of 136 pages Semi Best Practice Guidelines For Cleaning, Disinfection and Sterilization of Critical and critical Medical Devices In BC Health Authorities BC Ministry of Health First published March 2007 Reviewed revised December 2011 THIS DOCUMENT IS INTENDED TO DESCRIBE BEST Best Practice Guidelines For Cleaning, Disinfection and The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes (This task comes from Cambridge IELTS book 8) The first diagram illustrates the process of cement manufacture, and the second diagram shows the materials that go into the production of concrete It is clear that there are IELTS Writing Task 1: process diagram answer IELTS Simon

Cleaning shared Patient Care Equipment

Cleaning and washing patient care equipment, including slings Disposal sling as an alternative to mesh or fabric slings Only approved healthcare facility cleaning products to be used and be suitable to the cleaning process required Cleaning is still required if a cover has been used eg temperature probe cover Additional cleaning may be required in an outbreak situation Procedures Diagram of Area Use drawings of the plant layout or floor plans to help you draw a diagram Divide the workplace into areas based on the process Visualize the activities in the workplace and identify the location of machinery, equipment and materials Show the movement of material and workers, and the location of air ducts, aisles, stairways, alarms and fire exits Appendix A shows a sample Effective Workplace Inspections : OSH AnswersProcess flow diagrams (PFDs) are used in chemical and process engineering These diagrams show the flow of chemicals and the equipment involved in the process Generally, a Process Flow Diagram shows only the major equipment and doesn't show details PFDs are used for visitor information and new employee training A Process and Instrument Drawing (PID) includes more details than a PFD It Process Flow Diagrams (PFDs) and Process and Instrument

Cleaning Validation Protocol Pharmaceutical Guidance

The cleaning process of specified equipment for the specific product shall be revalidated in one or more of following cases Change of formulation procedures or quality of pharmaceutical ingredients Major changes of process parameters Change in facilities Equipment changes Changes in cleaning procedure On appearance of new findings based on current knowledge Batch size change Goods in/ out process Cleaning National Accounts: Document Ref: MFM(M)010/03 Cleaning Methodology and Processes (MAP) Manual One of the best ways to help reduce crosscontamination is to use colour code cleaning equipment so that certain tools and cloths etc are used only for certain tasks Document Ref: MFM(M)010/03 Cleaning Methodology and Processes (MAP) Manual Issue Cleaning Methodology and Processes (MAP) Issue Date: 04/10 Cleaning and washing patient care equipment, including slings Disposal sling as an alternative to mesh or fabric slings Only approved healthcare facility cleaning products to be used and be suitable to the cleaning process required Cleaning is still required if a cover has been used eg temperature probe cover Additional cleaning may be required in an outbreak situation Procedures Cleaning shared Patient Care Equipment

Cleaning Processes Hospital Environmental Services SMS

10Step Occupied Room Cleaning Process We utilize a 10step process that includes scripting for occupied room cleaning By training all EVS employees in this process, it guarantees consistency and accountability throughout your hospital Employees track the process using a Duty Checklist each time they clean a room Their work is monitored selectively by managers on rounds using our automated The cleaning process of specified equipment for the specific product shall be revalidated in one or more of following cases Change of formulation procedures or quality of pharmaceutical ingredients Major changes of process parameters Change in facilities Equipment changes Changes in cleaning procedure On appearance of new findings based on current knowledge Batch size change Cleaning Validation Protocol Pharmaceutical Guidance Cleaning and sanitation equipment used for food processing applications includes: Cleaning in Place (CIP) systems; Ball spray devices (for process and storage tanks) Dry steam vapor cleaners (for food processors and beverage production equipment) Design and Selection Considerations for Food Processing Equipment As outlined above, there is a wide range of food processing equipment Overview of Food Processing Equipment Types

How Dry Cleaning Works HowStuffWorks

The final phase of drycleaning operations includes finishing, pressing, steaming, ironing, and making any necessary repairs to restore the garment This is the least mysterious process since most drycleaning stores have their professional finishing equipment in plain view of customers Once the clothes are cleaned, they are pressed or Process flow diagrams (PFDs) are used in chemical and process engineering These diagrams show the flow of chemicals and the equipment involved in the process Generally, a Process Flow Diagram shows only the major equipment and doesn't show details PFDs are used for visitor information and new employee training A Process and Instrument Drawing (PID) includes more details than a PFD It Process Flow Diagrams (PFDs) and Process and Instrument The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes (This task comes from Cambridge IELTS book 8) The first diagram illustrates the process of cement manufacture, and the second diagram shows the materials that go into the production of concrete It is clear that there are IELTS Writing Task 1: process diagram answer IELTS Simon

LiquidLiquid Extraction Equipment

In this flow diagram, the aqueous feed stream containing the solute(s) to be extracted enters at one end of the process (A N+1)), and the fresh solvent (organic) stream enters at the other end (O 0) The aqueous and organic steams flow countercurrently from stage to stage, and the final products are the solvent loaded with the solute(s), O N, leaving stage N and the aqueous raffinate, depleted ConceptDraw is Professional business process mapping software for making process flow diagram, workflow diagram, general flowcharts and technical illustrations for business documents It is includes rich examples, templates, process flowchart symbols ConceptDraw flowchart maker allows you to easier create a process flowchart Use a variety of drawing tools, smart connectors, flowchart symbols Process Flowchart Draw Process Flow Diagrams by Starting