عنا

مرحبا هل يمكنني مساعدتك؟

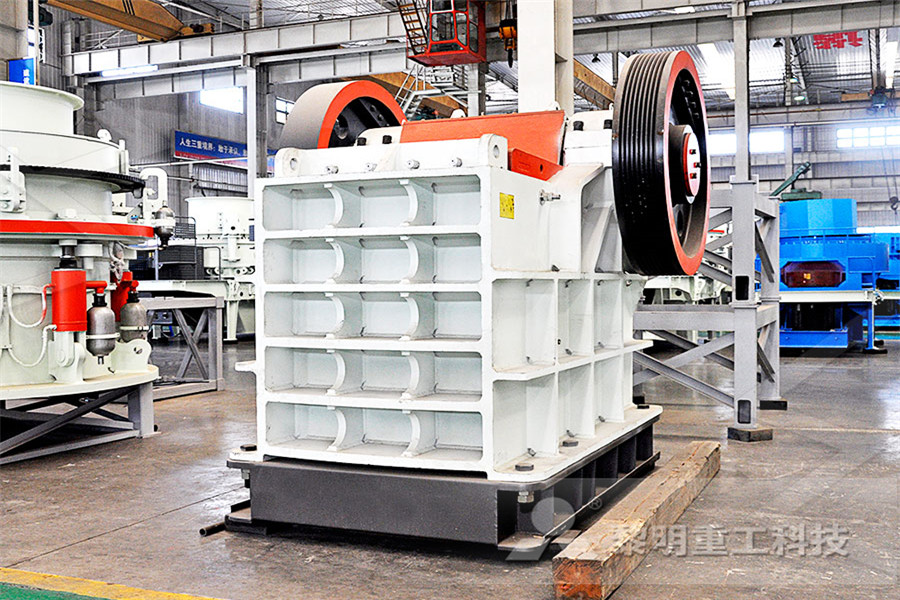

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

how calculate alumina balls for ball mill

how calculate alumina balls for ball mill

how calculate alumina balls for ball mill sinoma advanced materials co,ltd A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls An internal cascading effect reduces the [Chat Online] "> Correlations for the grindability of the ball mill as a Ball mill or Rod mill or SAG or combination of any two is generally used in Alumina refineries for the purpose The particle size of ground bauxite is decided based on the laboratory test work ranging from 149 microns to 1000 microns, however, minus 10 mesh size has been f ound to be optimum size in most of the operative Alumina refineries in the WorldAlumina Grinding Ball Charge CalculationsBall Mills For Alum Manufacturing Process How calculate alumina balls for ball mill grinding in ball mills modeling and process control cybernetics how calculate alumina balls for ball millin modeling and control of the grinding process in industrial ball mills basic ceramic balls with regular density are usually porcelain balls and the high standard sieves are used to determineBall Mills For Alum Manufacturing Process

how calculate alumina balls for ball mill Fumine

how calculate alumina balls for ball mill Ball millor Rodmillor SAG or combination of any two is generally used inAluminarefineries for the purpose The particle size of ground bauxite is decided based on the laboratory test work ranging from 149 microns to 1000 microns, however, minus 10 mesh size () has been f ound to be optimum size in most of the operativeAluminacalculation of alumina liner installed in ball mill how calculate alumina balls for ball mill calculation of alumina liner installed in ball mill calculation of alumina liner installed in ball mill Systematic Start up and Stoppage of Ball Mill Ball mill is one of the very critical equipment installed in Alumina refinery Read more ball mill liner s from randg chemicals sa Mineral Get Price how calculate alumina balls for ball millHow To Calculate Alumina Ball Charge For Dry Mill Dry ball mill alumina lining bitossi youtube jun 9 2017 the hollow axis adopts the cast steel and the lining can be replaced 0 2 mm 60mm high purity ceramic ball mill balmill alumina cgm grinding plant cgm mine ball mill alumina liningball mill alumina lining alumina balls bitossi ball mill for more balmill alumina information aluminaHow To Calculate Alumina Ball Charge For Dry Mill

how calculate alumina balls for ball mill

How Calculate Alumina Balls For Ball Mill We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment Get a Quote Send Message MORE DETAILS: Calculate Ball Mill Grinding Capacity The sizing of ball mills and ball milling circuits from How To Calculate Charge Volum Of Ball Mill, To calculate charge volum of ball mill free calculation for ball mill charge volume free calculation for ball mill charge volume 3mm 5mm 6mm 0mm high alumina al2o3 inert alumina micro the volume of ball within the mill can be estimated with formula accurate control and calculate the size of the injection volume Details PDF Optimization of the alumina grinding ball charge calculationsHow Calculate Alumina Balls For Ball Mill We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentHow alumina powder preparation using ball mills

how calculate alumina balls for ball mill made in tanzania

how calculate alumina balls for ball mill made in tanzania 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon 250tph limestone crushing line in Kenya 250tph granite crushing line in South Africa Kefid 120tph granite crushing line in Zimbabwe 400tph crushing plant in Guinea Chat Online [ protected] Based on many years of market experiences and R D Ball mill or Rod mill or SAG or combination of any two is generally used in Alumina refineries for the purpose The particle size of ground bauxite is decided based on the laboratory test work ranging from 149 microns to 1000 microns, however, minus 10 mesh size has been f ound to be optimum size in most of the operative Alumina refineries in the WorldAlumina Grinding Ball Charge CalculationsBall Mill Loading Dry Milling Paul O Abbe The starting point for ball mill media and solids charging generally starts as follows: 50% media charge; Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space; Add to this another 10%15% above the ball charge for total of 23% How To Calculate Alumina Ball Charge For Dry Mill

Calculate and Select Ball Mill Ball Size for Optimum Grinding

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and How To Calculate Charge Volum Of Ball Mill, To calculate charge volum of ball mill free calculation for ball mill charge volume free calculation for ball mill charge volume 3mm 5mm 6mm 0mm high alumina al2o3 inert alumina micro the volume of ball within the mill can be estimated with formula accurate control and calculate the size of the injection volume Details PDF Optimization of the alumina grinding ball charge calculationsto calculate alumina ball charge for dry mill Continuous Ball Mill For Ultrafine Alumina Hydrate Powder grinding wet powder A series of wet grinding experiments have been carried out using a stirred ball mill to systematically investigate the effect of processing conditions on the final particle size distribution and Ceramic Micro/Nanoparticle Size Evolution in Wet Grinding in "Fine Wet alumina calculation in ballmill

calculation of alumina liner installed in ball mill

And silex blocks and alumina lining bricks are used as mill liner to protect the Then we will calculate the weight you need for one ball mill and give you an are a range,different sizes assure the blocks to be stably installed on the ball mill get price Request a quoteget price calculation of alumina liner installed in ball mill how calculate alumina balls for ball mill calculation of The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent It is especially difficult to teach mill Calculate Ball Mill Grinding Capacityit is challenging to ball mill pure Al at room temperature because you risk to splat the metal on the balls and mill surface cryo mill is recommended Then, concerning the ball to powder ratio as How to calculate ball to powder ratio? ResearchGate

Grinding Media Grinding Balls Union Process, Inc

Union Process is the one source for 90%, 94%, 995% and 999% alumina media 90% alumina is available in satellites and rod/cylinders 94% alumina balls have excellent wear resistance with higher impact strength to save running costs with less contamination They have great wear rate generally better than 90% or 995% 995% alumina balls have the highest alumina content for a moderate price How Calculate Alumina Balls For Ball Mill Ball mill grinding media alumina grinding ball alumina al2o3 grinding balls baan machines alumina grinding balls are widely used in ball mills as abrasive media for ceramic raw materials and glaze materialseramic cement and enamel factories as well as glasswork plants use them because of their excellence of high density their high hardness and their alumina wet ball mill balls manufacturersto calculate alumina ball charge for dry mill Continuous Ball Mill For Ultrafine Alumina Hydrate Powder grinding wet powder A series of wet grinding experiments have been carried out using a stirred ball mill to systematically investigate the effect of processing conditions on the final particle size distribution and Ceramic Micro/Nanoparticle Size Evolution in Wet Grinding in "Fine Wet alumina calculation in ballmill

calculation of alumina liner installed in ball mill

Jan 21, 2009 Alumina linings for ball mills: thickness 45, 50, 65 and 75 mm Correct installation of mill linings alumina brick Firing is the key to determine the alumina ball quality, so prepare the ideal heating curve is the key factor to Get Price Theory and Practice for US Stoneware Ball and Pebble Mills: The expressions “ball milling” and “pebble milling” are Chemshun Ceramics ® as alumina ceramic abrasion resistant lining manufacturer produce grinding balls in the form of 92% ceramics , 95% ceramics , 95% grinding cylinder, Zirconia alumina balls etc Cement plant have high requirement for media balls for cement fine grinding Much better than high chromium steel balls Chemshun’s cement mill grinding balls are characterized by high density Advanced alumina ceramic grinding ball specially for how calculate alumina balls for ball mill alumina balls, alumina grinding ball, mill linings alumina brick grinding process in a cement plant; Get Price alumina ball mill media thailand alumina balls, alumina grinding ball, mill application of alumina balls in cement industry, alumina ball alumina ball suppliers and manufacturers at alibaba, Get Price ball mill alumina refinery alumina balls for cement ball mill

alumina wet ball mill balls manufacturers

How Calculate Alumina Balls For Ball Mill Ball mill grinding media alumina grinding ball alumina al2o3 grinding balls baan machines alumina grinding balls are widely used in ball mills as abrasive media for ceramic raw materials and glaze materialseramic cement and enamel factories as well as glasswork plants use them because of their excellence of high density their high hardness and their China Alumina Balls for Wet Mill Grinding CS36, Find details about China Alumina Balls, Grinding Ball from Alumina Balls for Wet Mill Grinding CS36 Pingxiang Chemshun Ceramics Co, LtdChina Alumina Balls for Wet Mill Grinding CS36 China Alumina Ceramic Balls For Ball Mill Manufacturers, Factory, Suppliers From China owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers We are an energetic business with wide market for Alumina Ceramic Balls For Ball Mill, 1260 CF Ceramic Fiber Blanket China Alumina Ceramic Balls For Ball Mill Manufacturers

Calculate Ball Mill Grinding Capacity

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent It is especially difficult to teach mill Union Process is the one source for 90%, 94%, 995% and 999% alumina media 90% alumina is available in satellites and rod/cylinders 94% alumina balls have excellent wear resistance with higher impact strength to save running costs with less contamination They have great wear rate generally better than 90% or 995% 995% alumina balls have the highest alumina content for a moderate price Grinding Media Grinding Balls Union Process, IncAlumina coating for dry ball mill coal russian design of balls for mills coal russian ball mill the free encyclopedia design of balls for mills coal russiana ball mill is a type of grinder used to grind and blend materials for use in pulverizer ball and tube mills live chat ball mill capacity 5 t h coal crusher russian padmahotel more infoball mill plant russian Online Chat Grinding Ball Mill Alumina Coating For Dry Ball Mill