عنا

مرحبا هل يمكنني مساعدتك؟

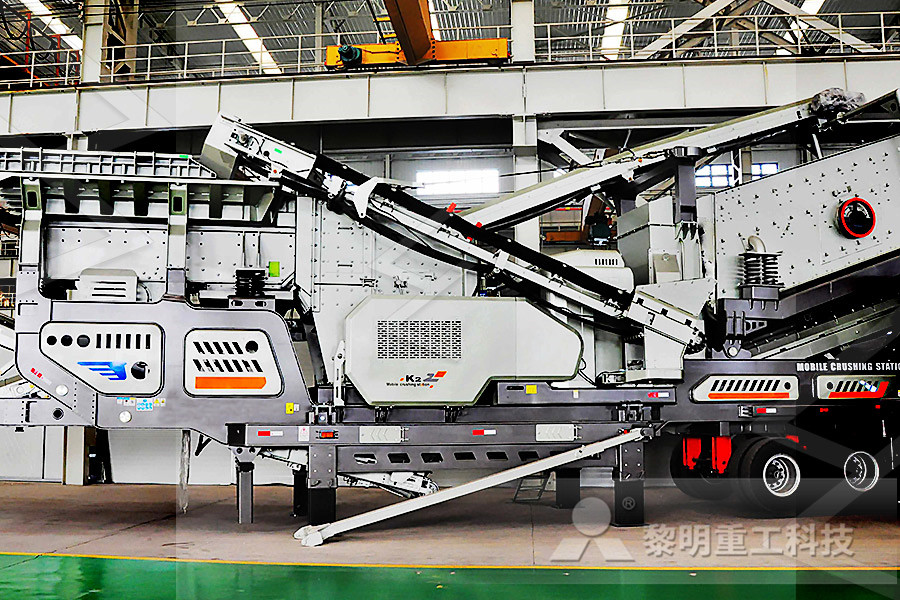

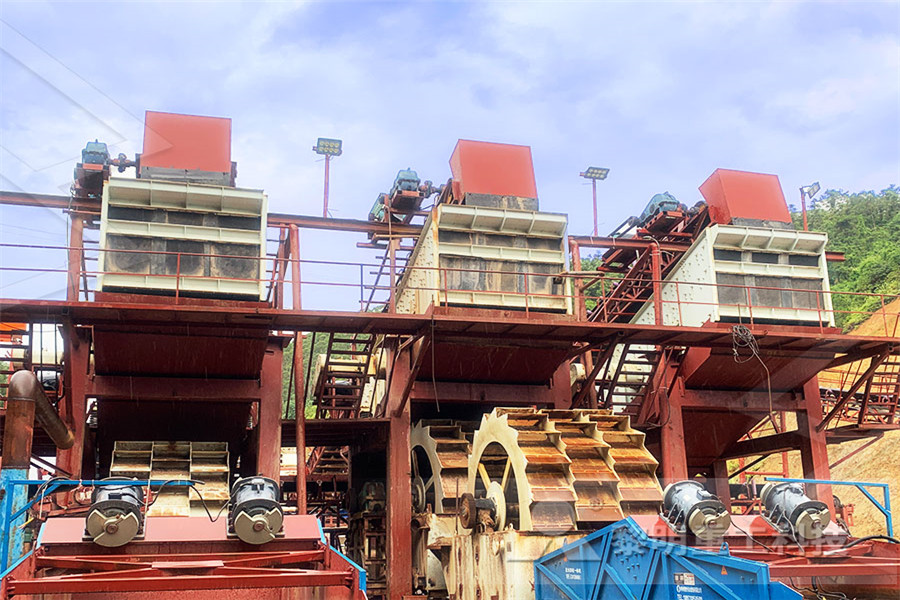

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Can Do Improve Cement Mill Production

How Can Do Improve Cement Mill Production Henan Heavy

How Can Do Improve Cement Mill Production Just Add Seawater: Ancient Roman Concrete Gets Stronger There hardeners that can be added to concrete to improve setting time, and make it harder, which are mainly salt, so the knowledge seems to exist in the modern trade, but it may be the cost Process Of Cement Mill Manufacturing So cement is kind of cementitious material which will be of Improve The Capacity Of Cement Grinding Machine And it is an eternal topic about how to improve the cement mill output and fineness, in the grinding process,the cement mill high efficiency and low power operation has been the target of building materials,cement production enterpriseer the past decade,both inland and abroad do a large number of applied research for cement mill about How To Increase Cement Mill Production twodonlCement Production Cement Sustainability Initiative 30% of global cement production) operating in more than 100 countries, who believe Other "alternative" raw materials such as mill scale, fly ash and slag are 3 to 6 stages of cyclones with increasing heat recovery with each extra stage Read morehow to improve production of cement mill

how can do improve cement mill production

o Cement manufacture consumes typically 3,100 3,400 MJ of fuel/t clinker 90 production, the heat generated can increase mill temperature to > 120⁰ C o Heattreated, rolled steel slotted plates do not peen over require almostHow to improve Cement mill production Generally speaking, there are three kinds of direct way to improve the mill production: A Set the fine crusher in front of the mill; Two Improved grinding system, to improve the grinding efficiency; 3 Plus set a high efficiency separator The three methods mentioned above, any one kinds can greatly improve the yield of the ball mill Of course, if the nicole006py How to improve Cement mill productionIn Europe, cement production decreased by 269% from 1990 to 2012, whereas CO 2 emissions decreased by 386%, showing an improvement in the cement production (CEMBUREAU, 2014) However, to reach the objectives of various sustainability programs, further efforts must be made in order to improve every step in the concrete production line For concrete, the main solutions for reducing Cement Production an overview ScienceDirect Topics

how can do improve cement mill production

how can do improve cement mill production djjohal The cement mill Understanding Cement Brief description of a cement mill Cement manufacturing Clinker grinding uses a lot of energy and the cement becomes hot this can result in the gypsum understanding of how cement is made, do have a look at the Understanding Cement book or ebook Chat Now how to improve cement mill production how can do improve cement mill production in malawi; how can do improve cement mill production in malawi In Europe cement production decreased by 269 from 1990 to 2012 whereas CO 2 emissions decreased by 386 showing an improvement in the cement production CEMBUREAU 2014 However to reach the objectives of various sustainability programs further efforts must be made in order to improve how can do improve cement mill production in malawiHOW Can Do Improve Cement Mill Production How can do improve cement mill productionow can do improve cement mill production how led strobes make steel mill production more by leveraging the latest led technology for surface inspection, steel coil mills and coaters can improve the consistency of coil quality, eliminate dochat online efficiency increase in ball millHow Can Do Improve Cementmill Production

How Can Do Improve Cement Mill Production

How Can Do Improve Cement Mill Production groundgranulated blastfurnace slag ggbs or ggbfs is obtained by quenching molten iron slag a byproduct of iron and steelmaking from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a Some data on worldwide cement production will set the framework for this discussion Of all the energy expended in the nonmetallic mineral sector (∼9% of total global energy use), manufacture of cement accounts for 70–80% The weighted average among cementproducing countries for specific energy consumption comes to 44 GJ per tonne of product China produces nearly onehalf of all cement Cement Industry an overview ScienceDirect Topics MPC systems can deliver optimization across key areas of the production process through applications for raw material preparation, including pyroprocessing, cement grinding, and material blending Energy savings can be generated by optimizing the combustion process, controlling temperature profiles, optimizing the heat recuperation process, and others On average, MPC systems allow cement Reduce Energy Consumption: Cement Production

Increase the productivity of your cement plant

Increase the productivity of your cement plant Are you looking to invest in a new plant, increase the capacity of an existing site, or investigating productivity improvements? As a full flowsheet provider with more than 135 years of experience in the cement industry, we are ready to assist you through the entire lifecycle of your plant However, the operation itself can be optimized for reducing the airflow and improving production, which contribute to the kWh/t of fans The mills are large consumers of power as well In the case of ball mills, optimization of the mill charge helps to minimize the power consumption of the mills In the case of vertical roller mills, inspection OPTIMIZING OPERATING COSTS TO IMPROVE PROFITABILITY IN Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using s, from lakes, rivers and waterways There are a few underground limestone mines, but most are pits on the surface Cement plants are typically located central to the minerals required to make the cement, which saves the transportation costs and Cement, How It Is Produced

Cement plant performance optimization Benchmarking

Production increase Reduction in specific energy consumption More consistent product quality Reduction in the consumption of grinding media Extensive diagnostic features Cement plant performance optimization Holistic energy management Mix bed blending Raw mix preparation Precalciner, Kiln and Cooler control Mill controlSEC = Electric Power / Cement Production Cement Mill Laos 200610 19 Recording of SEC on the Graph Raw mill SEC (kWh/kgmat’l) Oct2 Oct9 Oct16 Oct23 Oct30 Nov6 Addition of Grinding Balls Watch raw mill SEC daily and add grinding balls in right timing →10% energy saving expected Ball diameter shrinks as time passes due to erosive effect This leads to gradual increase of raw mill SEC Cement Process Energy Saving ECCJAfter cooling, the clinker may be stored temporarily in a clinker store, or it may pass directly to the cement mill The cement mill grinds the clinker to a fine powder A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker The gypsum controls the setting properties of the cement when water is addedCement manufacturing components of a cement plant

Cement CO2 Emissions Global Greenhouse Warming

• Cement production is an important source of CO2 emissions, accounting for 18 Gt CO2 in 2005 Half of cement process CO2 emissions are due to the chemical reaction in cement clinker production These process emissions are not affected by energy efficiency measures Yet it might be possible to reduce clinker production by 300 Mt with more extensive use of clinker substitutes which could Having gained a clear sense of market dynamics and opportunities, cement company CEOs can then define their own company’s objectives, determine on which micromarkets to focus, and whether to position the company as a premium player or a lowcost producer They can then set marketshare aspirations, anticipate potential changes, and develop a set of strategic initiatives to address How cement companies create value: The five elements of a Increase the productivity of your cement plant Are you looking to invest in a new plant, increase the capacity of an existing site, or investigating productivity improvements? As a full flowsheet provider with more than 135 years of experience in the cement industry, we are ready to assist you through the entire lifecycle of your plantIncrease the productivity of your cement plant

Reduce Energy Consumption: Cement Production

Reduce Energy Consumption: Cement Production How conducting manufacturing energy assessment can help identify a wide range of changes to help reduce consumption Metering, power quality, load shedding, motor management, power factor, and energy optimization all can help cement operations and other plants, as well By Patrick Murray August 25, 2011variety of waste fuels, including tires, steadily increase their share in fuel use Between 1970 and 2010, primary physical energy intensity for cement production dropped 12% per year from 73 MBtu/short ton to 45 MBtu/short ton Carbon dioxide intensity due to fuel consumption and raw material calcination dropped 24%, from 610 lb C/ton of cement (031 tC/tonne) to 469 lb C/ton cement (023 Energy Efficiency Improvement and Cost Saving Cement FingerPrint ABB’s Cement FingerPrint is a process optimization and energy consulting service designed to capture, analyze and improve operational performance and energy efficiency of Cement plant performance optimization Benchmarking

Cement mill notebook SlideShare

In cement grinding the mill ventilation system fulfils two important functions, cooling the cement and removing the heat generated during the grinding process, and carrying part of the finished product out of the grinding area It is well known that the energy used during the grinding process in ball mills is almost entirely converted into heatDomestic cement production has been increasing steadily, from 664 million tons in 2010 to about 805 million tons of Portland cement in 2014 according to the US Geological Survey 2015 Cement Mineral Commodity Summary The overall value of sales of cement was about $89 billion, most of which was used to make an estimated $48 billion worth of concrete Most construction projects involve some The Cement Manufacturing Process Advancing MiningSEC = Electric Power / Cement Production Cement Mill Laos 200610 19 Recording of SEC on the Graph Raw mill SEC (kWh/kgmat’l) Oct2 Oct9 Oct16 Oct23 Oct30 Nov6 Addition of Grinding Balls Watch raw mill SEC daily and add grinding balls in right timing →10% energy saving expected Ball diameter shrinks as time passes due to erosive effect This leads to gradual increase of raw mill SEC Cement Process Energy Saving ECCJ

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

The most common raw materials used for cement production are limestone, chalk and clay The major component of the raw materials, the limestone or chalk, is usually extracted from a quarry adjacent to or very close to the plantHalf of cement process CO2 emissions are due to the chemical reaction in cement clinker production These process emissions are not affected by energy efficiency measures Yet it might be possible to reduce clinker production by 300 Mt with more extensive use of clinker substitutes which could reduce CO2 emissions by about 240 Mt CO2 per yearCement CO2 Emissions Global Greenhouse WarmingBall Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using s, from lakes, rivers and waterways There are a few underground limestone mines, but most are pits on the surface Cement plants are typically located central to the minerals required to make the cement, which saves the transportation costs and Cement, How It Is Produced