عنا

مرحبا هل يمكنني مساعدتك؟

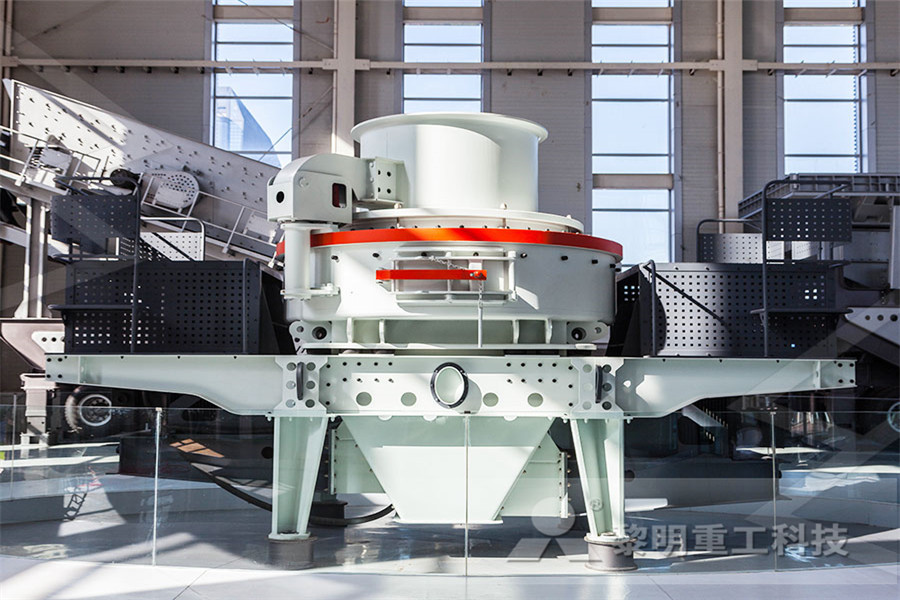

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

for separating gold ore

Gold parting Wikipedia

The very earliest attempts at refining gold can be shown by the surface enhancement of gold rings Gold quality was increased at the surface by 80–95% gold compared to 64–75% gold at the interior found in Nahal Qanah Cave dated to the 4th millennium BC Further evidence is from three gold chisels from the 3rd Millennium BC royal cemetery at Ur that had a surface of high gold (83%), low silver (9%) and copper (8%) compared with an interior of 45% gold, 10% silver and 45% copper The surface was compacted Several processes can then be used to separate the gold from the ore The most common techniques in the United States use cyanide in various ways In one, the ground ore is put into a tank containing a weak cyanide solution and zinc is added The zinc causes a chemical reaction which separates the gold from the ore The gold is then removed from the solution with a filter press For the carbon How Is Gold Extracted From Gold Ore? Sciencing Leaching dissolves the gold out of the ore using a chemical solvent The most common solvent is cyanide, which must be combined with oxygen in a process known as carboninpulp As the cyanide and oxygen react chemically, gold in the pulp dissolves When workers introduce small carbon grains to the tank, the gold adheres to the carbonExtracting Gold HowStuffWorks

How to Use Bleach on Gold Ore to Remove Gold Sciencing

Pour the acidandbleach mixture into the plastic bowl with the ore grains and stir Allow four hours for the gold to dissolve, stirring every 20 minutes The chlorine reacts with the gold inside the ore to form gold chloride Filter the ore and bleach solution to remove all the impurities, such as soil and rock fragmentsFoaming agent: Foaming agent for separation of gold and silver ores, commonly used are 2 # oil, turpentine, camphor oil, dipyridine and formic acid, the amount of which is generally 20100 g/t Camphor oil has good selectivity and is mostly used to obtain high Froth Flotation Method JXSC Machine You must heat the gold containing copper ore until it becomes molten With the gold being a heavy metal than copper, the gold will settle to the bottom and then you can pour off the copperHow do you separate gold from copper? Yahoo Answers

Cornstarch Replaces Cyanide In Gold Extraction Popular

Bound up in consumer electronics, jewelry and the ores that it comes from, gold is difficult to extract, and most modern processes do it with a highly toxic combination of cyanide salts TheProcesses of gold ore separation 102620; 17 Views; icon 0; Processes of gold ore separation The three most commonly used processes for gold ore separation are: gravity separation, flotation and cyanidation Among them, gravity separation is a commonly used process in placer gold mines, flotation is mostly used in rock gold mines, and cyanidation is suitable for refractory gold ores such Processes of gold ore separation,the process of gold Separating the gold from the ore 4 The gold is then separated from the ore using one of several methods Floatation involves the separation of gold from its ore by Processing, smelting and refining gold World Gold Council 4 days ago More gold is recovered by cyanidation than by any other process For extracting gold from lowgrade ores, heap leaching is practiced; huge Gold processing industrial process for the separation of gold ore

How Is Gold Extracted From Gold Ore? Sciencing

Several processes can then be used to separate the gold from the ore The most common techniques in the United States use cyanide in various ways In one, the ground ore is put into a tank containing a weak cyanide solution and zinc is added The zinc causes a chemical reaction which separates the gold from the ore The gold is then removed from the solution with a filter press For the carbon It can strengthen the separation effect of goldsilver quartz vein ore and goldsilver ore associated with nonferrous metals, and has the dual functions of collecting and foaming Foaming agent: Foaming agent for separation of gold and silver ores, commonly used are 2 # oil, turpentine, camphor oil, dipyridine and formic acid, the amount of which is generally 20100 g/t Camphor oil has good Froth Flotation Method JXSC MachineEndogenetic gold ores include vein and lode deposits of elemental gold in quartzite or mixtures of quartzite and various iron sulfide minerals, particularly pyrite (FeS 2) and pyrrhotite (Fe 1x S) When present in sulfide ore bodies, the gold, although still elemental in form, is so finely disseminated that concentration by methods such as those applied to alluvial gold is impossibleGold processing Britannica

Separation Of Gold From Its Ore

Separating gold from iron ore mining machineryeparating gold ore from other rocksprocess of separating the iron ore from other rock process of separating the iron ore from other rock,ehow separating gold from rock ore is a multi step processvibrating shaker table for gold iron zircon ore separation,us 600 1,998 set,new,goldget price Separation Of The Ore From The Other Rock Jan How to Separate Gold From Ore Separating gold from rock ore is a multistep process that involves grinding the rock how to building a micron gold recovery device; Get Price Black sand gold concentrators Gold Fever Prospecting Black sand gold concentrators the best in mechanical gold separation equipment Save time and aggravation and recover more of your fine gold quickly and Devices For Separating Gold Ore cooperativesuissechSpiral Chute Physical Separation Of Gold Ore Low Consumption Gold CIL process Yantai Jinpeng Mining The gold CIL process is mainly used in the oxide ore which has low grade of manganese ore mining gold mining machine gold mining investment mining for copper crusher for gold mining process of melting gold ball mill grinder nickel mining process carbon in pulp Magnetite Separation Spiral Chute Physical Separation Of Gold Ore Low Consumption

How do you separate gold from copper? Yahoo Answers

When mining copper ore, containing gold, what is the simplest approach to separating them to solid components Gold CopperHow to separate gold from ore after crushedold crushed ore separation crusherasia posts related to crushing rock for gold separation of ore from rocks the need to crush the ore bearing rock of gold,how to separate gold from ore after crushedore info smelting and roasting ores to recover gold, silver and ,get price Silica Iron Ore Silver Seperation Machine Silica iron ore silver seperation Machine To Separate Gold From Iron OresProcesses of gold ore separation 102620; 17 Views; icon 0; Processes of gold ore separation The three most commonly used processes for gold ore separation are: gravity separation, flotation and cyanidation Among them, gravity separation is a commonly used process in placer gold mines, flotation is mostly used in rock gold mines, and cyanidation is suitable for refractory gold ores such Processes of gold ore separation,the process of gold

industrial process for the separation of gold ore

Separating the gold from the ore 4 The gold is then separated from the ore using one of several methods Floatation involves the separation of gold from its ore by Processing, smelting and refining gold World Gold Council 4 days ago More gold is recovered by cyanidation than by any other process For extracting gold from lowgrade ores, heap leaching is practiced; huge Gold processing Several processes can then be used to separate the gold from the ore The most common techniques in the United States use cyanide in various ways In one, the ground ore is put into a tank containing a weak cyanide solution and zinc is added The zinc causes a chemical reaction which separates the gold from the ore The gold is then removed from the solution with a filter press For the carbon How Is Gold Extracted From Gold Ore? SciencingI live near the site John Marshall discovered gold in 1848 There is gold dust and particles everywhere! Problem is that the gold is dust or fine powder form and the gold strongly adheres to it's surrounding ores Panning is tedious and not effective How can I separate the gold dust/powder from the other minerals? I have heard using Auger How do I separate gold from surrounding ores Instructables

Knelson Concentrator Gravity Separation of Polymetallic

Study on Knelson Concentrator Gravity Separation of a Polymetallic Ore Bearing Gold The major methods of recovering gold are gravity separation, gold flotation, cyanide In fact, traditional gravity separators, such as jig machine, spiral chute, gold shaker table, have the shortages of low beneficiation ratio and low productivity In addition, the flotation process is difficult to work on the Finally, once the rock is fully crushed we get to the part about separating out the gold from the crushed rock Often, this is accomplished simply by very careful panning Panning is the most suitable method if you only have an amount of rock less than about 15 or 20 pounds On the other hand if you are going to be processing large quantities of rock on a regular basis such as would come from Rock Crushing methods and How to recover gold from Ores Physical separation usually involves the difference in mass between gold and most of the other associated minerals Once the gold is physically separated from the host material and of a relatively similar size it can be separated using a rotary boWhat are the chemical and physical separation methods used

How do i separate gold from sulphides without using

My freind has a large supply of microscopic gold particles, however they need to be separated from sulphides there is a high concentration of gold in this solution, and millions of dollars could be made however, heating the sulphides will make sulpheric acid, which burns away your lungs (also used in chemical warfare) chemicals currently used for the process of separating sulphides from How to Separate Gold From Ore Separating gold from rock ore is a multistep process that involves grinding the rock how to building a micron gold recovery device; Get Price Black sand gold concentrators Gold Fever Prospecting Black sand gold concentrators the best in mechanical gold separation equipment Save time and aggravation and recover more of your fine gold quickly and Devices For Separating Gold Ore cooperativesuissech how do you balance the equation for gold extraction from gold ore Au+2NaCN+O2+H2O>NaAu(CN)2+3NaOH? I know the basics but I just cannot balance this equation Answer Savehow do you balance the equation for gold extraction from