عنا

مرحبا هل يمكنني مساعدتك؟

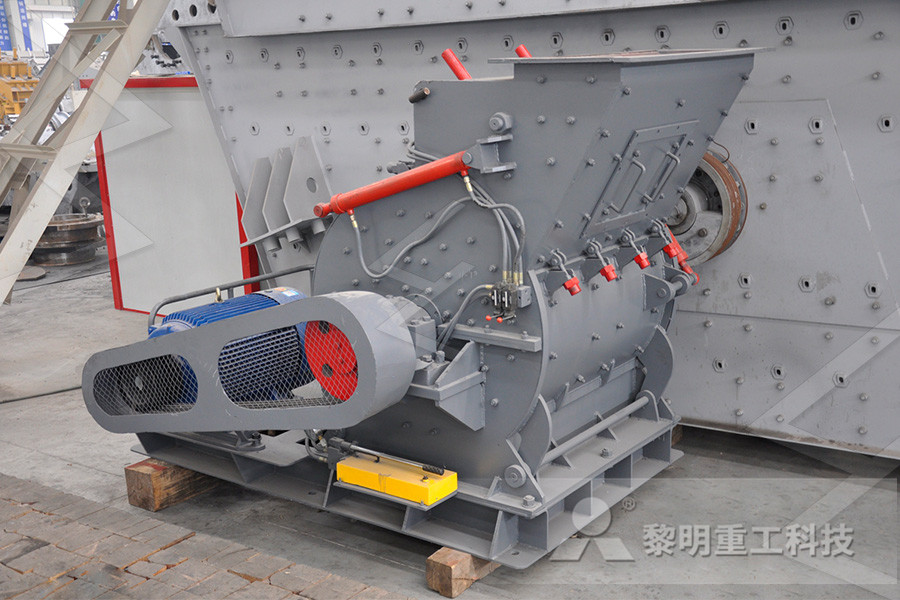

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

silica making cement

Crystalline Silica and Portland Cement Concrete

Limestone, clay and sand are commonly used in making portland cement In their raw form, these materials contain varying amounts of silicon dioxide But when they're blended and heated to high temperatures in the cement kiln, the resulting clinker contains new compounds What was originally crystalline silica has reacted to become part of the hydraulic calcium silicates According to Howard Diatomaceous silica and some natural amorphous silica deposits may also form pozzolans, either with or without a heat treatment PFA (or fly ash), a waste product from coalburning power stations, is now used in many countries on a large scale as a pozzolana Pozzolanic cements are produced by grinding together Portland cement clinker and a pozzolan, or by mixing together a hydrated lime and a Silicate Cement an overview ScienceDirect TopicsBoth Portland cement and MTA contain tricalcium and dicalcium silicate, which on hydration produce calcium silicate hydrate gel, calcium hydroxide, and calcium carbonate, and thus are able to exert remineralizing effects (Parirokh and Torabinejad, 2010; Watson Silicate Cement an overview ScienceDirect Topics

Cement Raw Materials used in Manufacturing of Cement

This plays a major role in imparting strength to concrete Silica undergoes a chemical reaction with calcium to form dicalcium silicate (C2S) and tricalcium silicates (C3S) Excess silica adds strength to cement but it prolongs the setting time 03 Alumina This forms complex compounds with silica and calcium to improve the setting capacity of the cement It acts as a flux and lowers the Workers who mix concrete may be exposed to silica Construction hazards with suggested options for making work safer Inhaling crystalline silica can lead to serious, sometimes fatal illnesses including silicosis, lung cancer, tuberculosis, and chronic obstructive pulmonary disease (COPD) When workers breathe in dust containing silica the lung tissue reacts by developing fibrotic nodules Hazard Analysis Reinforced Concrete Mix concrete Manufacture The cement is made by fusing together a mixture of a calciumbearing material (normally calcium oxide from limestone) and an aluminiumbearing material (normally bauxite for general purposes, or refined alumina for white and refractory cements)Calcium aluminate cements Wikipedia

Mixing bags of cement – overexposure? » Industrial Hygiene

Question: During mixing of portland cement bags of material (or similar types), am I overexposed? Maybe, likely But, probably not to silica Most manmade, off the shelf products do not contain freesilica, or respirable fraction of the dangerous parts of silica However, there is overexposure to respirable and total dust But, be forewarned, if the product has rocks in the material, these may Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore These ingredients, when heated at high temperatures form a rocklike substance that is How Cement Is Made You can also use silica on top of your wet concrete sealer After putting the silica sand layer, place a second coat of concrete sealer on top of it and you instantly have a finish that makes your concrete not slipperyHow to Make Concrete Not Slippery SealWithEase

What Is Silica Dust Why Is It So Dangerous Howden

Silica Exposure In Cement Production High levels of dust can be produced when cement is handled, for example when emptying or disposing of bags Scabbling or concrete cutting can also produce high levels of dust that may contain silica Find out more about Howden's Centrifugal Fans Most concrete and masonry products contain high amounts of silica When you cut or grind these products, you are being exposed to silica if measures are not taken Although most diseases associated with silica exposure are not curable, they are preventableSilica—Cutting and grinding concrete IHSA As a chemist specializing in silicone, he noted that silicon and silica are key ingredients of concrete He studied the chemical reaction and found it to be quite inefficient He said the more efficient a process is, the less byproducts there are, and that all the current problems with cement were related to the byproducts that were generatedSilicabasedadditivemixturecouldchangetheconcrete

Hazard Analysis Reinforced Concrete Mix concrete

Workers who mix concrete may be exposed to silica Construction hazards with suggested options for making work safer Inhaling crystalline silica can lead to serious, sometimes fatal illnesses including silicosis, lung cancer, tuberculosis, and chronic obstructive pulmonary disease (COPD) When workers breathe in dust containing silica the lung tissue reacts by developing fibrotic nodules Microsilica in concrete improves its strength and durability as it provides more uniform distribution and a greater volume of hydration products, and decreases the average size of pores in the cement pasteMicrosilica in Concrete Types, Properties, and Practical Sep 27, 2017 Silica is one of the varying components contained within the sand, rock and the cement used in the concrete mixture by contractors This rule will significantly impact Concrete Contractors Crystalline silica (SIo2) is the type used to make concrete as opposed to amorphous silicapurchaser of silica sand use in making cement

Cement Lafarge Canada

Special cements for specific applications: including white cements for architectural projects, cements for well drilling operations, cements containing silica fume or slag, pozzolan cements, and cements for road surfacing that incorporate slag and hydraulic binders Cements for masonry and mortars for concrete blocks, tiles, rendering, stucco, etc You can also use silica on top of your wet concrete sealer After putting the silica sand layer, place a second coat of concrete sealer on top of it and you instantly have a finish that makes your concrete not slipperyHow to Make Concrete Not Slippery SealWithEasePortland silica fume cement Addition of silica fume can yield exceptionally high strengths, and cements containing 5–20% silica fume are occasionally produced, with 10% being the maximum allowed addition under EN 1971 However, silica fume is more usually added to Portland cement at the concrete mixer Masonry cements are used for preparing bricklaying mortars and stuccos, and must not be Cement Wikipedia

How to Make Ultra High Performance Concrete Hunker

Mix your coarse aggregate with silica fume Pour the course aggregate into your cement mixer and add just enough water to get the stones damp Turn on the mixer and begin to slowly add the silica fume The amount of silica should be roughly 4 to 5 percent (by weight) of the amount of course aggregate(Editor's note: after fabrication, most of the silica in portland cement may be amorphous silica As explained below, according to NIOSH, PC can contain less than one percent crystalline silica, while OSHA defines PC as a substance that can contain greater than one percent crystalline silica) An exact figure is elusive due to variations in formula by type, the effects of additives, and the A Close Look at Portland Cement The SynergistIn concrete applications, such as shotcrete, SCC (self compacting concrete) and precast, Levasil Colloidal Silica works exceptionally well as a stabilizer, a durability enhancer, an accelerator and a strength developer Colloidal silica produces extremely stable, bleedfree cement Concrete with Levasil Colloidal Silica – Nouryon

Silica—Cutting and grinding concrete IHSA

Silica—Cutting and grinding concrete • Use a respirator An N95 filtering facepiece respirator (ie, dust mask) may be appropriate when doing shortduration tasks, when local exhaust ventilation is available on tools, or when working outside Otherwise, a more protective respirator is required Minimum protection is a halffacepiece airpurifying respirator with an N95 filter • Before Silica fume concrete shrinkage rate is large, especially early dry shrinkage, easy to make crack in the application of silica fume concrete, affect the overall strength and using effect For example, after construction, strengthening water and sprinkler maintenance can decrease this problem, but the cracks are still unavoidable in many construction projectsSilica fume advantages and disadvantages in concrete Workers who mix concrete may be exposed to silica Construction hazards with suggested options for making work safer Inhaling crystalline silica can lead to serious, sometimes fatal illnesses including silicosis, lung cancer, tuberculosis, and chronic obstructive pulmonary disease (COPD) When workers breathe in dust containing silica the lung tissue reacts by developing fibrotic nodules Hazard Analysis Reinforced Concrete Mix concrete

Cement Lafarge Canada

Special cements for specific applications: including white cements for architectural projects, cements for well drilling operations, cements containing silica fume or slag, pozzolan cements, and cements for road surfacing that incorporate slag and hydraulic binders Cements for masonry and mortars for concrete blocks, tiles, rendering, stucco, etcPortland cement (You can purchase a 94 lb bag at your local hardware store for less than $10) Perlite (Can be purchased for $10 to $25) Silica Sand (A 50 lbbag costs less than $25) Fire clay or Well drillers mud (A 50 lb bag averages less than $10) The Formula 15 parts Portland cement + 2 parts Perlite + 2 parts silica sand + 2 parts How to Make Refractory Cement 3+ Recipes It might surprise you to know that concrete and cement dust contains silica If you don't know much about silica, in dust form, it's deadly Silica dust is one of the biggest killers of construction workers, second to asbestos Silica dust kills around 800 people every year in the UK Concrete and mortar can contain up to 25%70% silica so concentrations can be pretty high The higher the Concrete And Cement Dust Health Hazards HASpod

How to Make Ultra High Performance Concrete Hunker

Making concrete is a delicate balance, particularly if you are going to make ultra high performance concrete The standard ratio is 11 percent Portland cement, 41 percent coarse aggregates (such as gravel or crushed stone) and 26 percent fine aggregates, such as sand The remaining 22 percent is a combination of air and water (6 percent air and 16 percent water) in most concrete, but in ultra The mix ratio of 1:2:3 consists of 1 Part cement, 2 Parts sand, and 3 Parts stone (plus some water) to make a concrete mix you can use for most any building project The way you measure the ratio could be in shovels, buckets, or wheel barrows As long as you're consistent you'll get a good strong mix Generally, when the stone ratio is more than the sand, this concrete cures a little stronger Concrete Mixing Ratios How To Make Concrete (Cement