عنا

مرحبا هل يمكنني مساعدتك؟

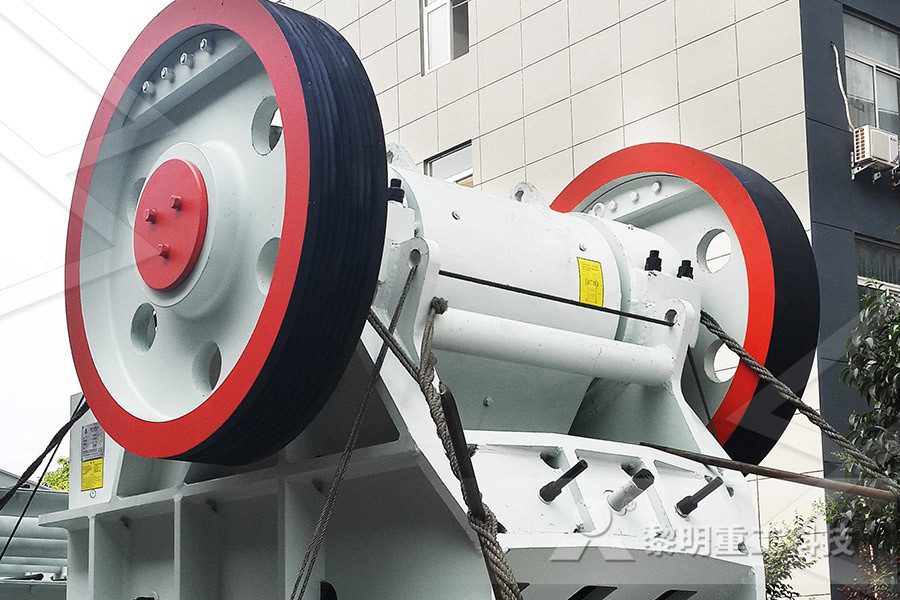

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crusher plant safety de of practice

Enhancing safety around crushers : Pit Quarry

Safety on a crusher starts with the person feeding the plant The person feeding the plant needs to be trained on best practices specific to the crusher they are working with An operator may have years of experience operating and loading a cone crusher, but that doesn’t translate into experience loading and operating a jaw crushercrusher plant safety code of practice Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining crusher plant safety code of practice Mobile Crushers california health and safety code table of contents general provisions local administration chapter 5 local health and safety regulations safety inspection checklist for crushing plant work health and safety codes of practice 2011 codes codes of practice as made this instrument enacts approved codes of practice providing practical guidance to mobile crusher safety checklist safety codes for crusher Mining Quarry Plant

NFDC Safe Use of Mobile Crushers Screening Plant by

INTRODUCTION The National Federation of Demolition Contractors (NFDC) is represented on the British Standards subcommittee which prepares the code of practice for demolition (BS6187Code of practice for in pit crusher in mining Code of practice for in pit crusher in mining crusher plant safety code of practice crusher plant safety code of practice code of practice for in pit crusher in mining as one of the largest mining and crushing equipments manufacturers and get pricCrusher Plant Safety Code Of Practice masalateaplCode of Practice for Deconstruction and Construction Sites This is the seventh version of the Code of Practice developed by the City of London's Pollution Control Team to site, thereby ensuring minimal traffic disturbance and pedestrian safety 337 Vehicle Any crushing plant crusher plant safety code of practice

Safe and sound: Crusher safety : Pit Quarry

To Smith, one of the key factors that should be addressed related to crusher safety is a company’s workforce A number of people operating and working around crushing equipment don’t have the adequate experience, he says Producers and recyclers sometimes turn to a transient workforce, and that can present problems “Our industry is so much about tribal knowledge,” Smith says “We Crusher Plant Safety Code Of Practice Chapter 74 Mining and Quarrying ilocisorg The significant environmental effects of surface mines attract attention wherever the mines are located [Online Chat] PQ University Lesson 7 Crushing Secondary Breaking , In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary The reduction of aggregates is crusher plant safety code of practice dovykeukensfccbeSrg Wirecrafts Pvt Ltd Gypsum crushercoal crusher powersamAIPS srg wirecrafts pvt ltd coal crushersdietisthoofddorp crusher plant safety code of practice Mobile and Fixed, srg wirecrafts pvt ltd coal crushers safe code of practice for in pit crusher and coal srg wirecrafts p As a common building material, limestone is widely used in cement, decoration, building materials and other industries Srg Wirecrafts Pvt Ltd Gypsum crusher

Managing Risks of Plant in the Workplace Code of Practice 2013

The Managing risks of plant in the workplace Code of Practice is an approved Code of Practice under section 274 of the Work Health and Safety Act 2011 (the WHS Act) To Smith, one of the key factors that should be addressed related to crusher safety is a company’s workforce A number of people operating and working around crushing equipment don’t have the adequate experience, he says Producers and recyclers sometimes turn to a transient workforce, and that can present problems “Our industry is so much about tribal knowledge,” Smith says “We Safe and sound: Crusher safety : Pit QuarryMINE SAFETY AND HEALTH ADMINISTRATION DAVE D LAURISKI ASSISTANT SECRETARY Originally Published AUGUST 2000 INSTRUCTION GUIDE SERIES MSHA IG 40 MODULE NUMBER 17 OF INSTRUCTION GUIDE NUMBER 40 ONTHEJOB TRAINING FOR THE SAND, GRAVEL, AND CRUSHED STONE INDUSTRY PRIMARY CRUSHING OPERATION This module describes basi c SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING

Model Code of Practice Managing risks of plant in the

This Code of Practice on managing health and safety risks of plant in the workplace is an approved code of practice under section 274 of the Work Health and Safety (WHS) Act An approved code of practice is a practical guide to achieving the standards of health, safety and welfare required under the WHS Act and the Work Health and Safety (WHS) Regulations A code of practice applies to Updated: January 2020 View the Codes of Practice and Maps below, or you can purchase print copies from Alberta Queen's Printer Environmental Protection and Enhancement Act Codes of Practice Code of Practice for a Waterworks System Consisting Solely of a Water Distribution SystemAlberta Queen's Printer: Codes of PracticeThe Guide to Food Safety is based upon the Recommended International Code of Practice General Principles of Food Hygiene adopted by the Codex Alimentarius Commission (Codex) in 2003 It is consistent with Codex's recommendations to enhance food safety by applying a systematic preventive approach The Guide to Food Safety is outcomebased It Guide to Food Safety Canadian Food Inspection Agency

Plant and equipment safety procedures

UWA Plant and Equipment Safety Procedures 1 of 20 Plant and Equipment Safety Procedures Contents: Codes of Practice and Guidance Notes and all relevant laws pertinent to plant which include: identification, risk assessment and control of hazardous plant, provision of personal protective equipment (PPE), induction and training, standard operating procedures (SOP), emergency CODE OF PRACTICE SAFEGUARDING OF MACHINERY AND PLANT Foreword This code of practice is issued by the Commission for Occupational Safety and Health (the Commission) and its Mining Industry Advisory Committee under the provisions of the Occupational Safety and Health Act 1984 (the OSH Act) and the Mines Safety and Inspection Act 1994 (the MSI Act)Code of practice Safeguarding of machinery and plantIf your work involves machinery and equipment (plant), there are specific duties and obligations you need to comply with under the Occupational Health and Safety Act (OHS Act) 2004 and Occupational Health and Safety Regulations (OHS Regulations) 2017 This compliance code gives you practical guidance on how to comply with those duties and pliance code: Plant WorkSafe

Working with or around mobile plant safety alert

SafeWork NSW has already issued a safety alert and a code of practice outlining the risks and hazards of mobile plant on construction sites At the time, these publications were targeted primarily at the construction industry However, working with or around mobile plant is a potential risk at any workplace with mobile plant Action required Work health and safety legislation requires PCBUs 106 Materials Plant Sites (Safety Manual), portions of the Construction Manual and Standard Specifications, and contractspecific standard special provisions dealing with safety In addition to the COSP, the resident engineer should be familiar with the provisions of the California Code of Regulations, Title 8 (CCR Title 8), “Industrial Relations,” applicable to the work in order to CODE OF SAFE PRACTICES California Department of Crushing plant is stopped, cleared of blocked materials and restarted as required, according to manufacturer instructions and site safety plan 25 Crushing plant settings are maintained according to manufacturer instructions 26 Work is completed according to requirements and within the operating capacity of the allocated equipmenttraininggovau CPCCDE3021A Operate demolition

FARM SAFETY CODE OF PRACTICE Health and Safety Authority

involving machinery are crushing, being struck and entanglement Those at risk of injury are persons operating the machinery and those in the vicinity when machinery is being operated PTO Entanglement 32% (12) Caught in machine mechanism 18% (7) Machine object flying 5% (2) Crushed between tractor and machinery 11% (4) Crushed under machinery part 18% (7) Struck by trailer or machine 16% (6) processing plant Section 5 of this Code deals with registration in greater detail Introduction 2(1) This Code of Practice outlines the design and operating requirements that persons responsible for compressor and pumping stations and sweet gas processing plants must meet to ensure environmental protection Persons responsible for these facilities within the Province of Alberta must comply Code of Practice for Compressor and Pumping Stations and Updated: January 2020 View the Codes of Practice and Maps below, or you can purchase print copies from Alberta Queen's Printer Environmental Protection and Enhancement Act Codes of Practice Code of Practice for a Waterworks System Consisting Solely of a Water Distribution SystemAlberta Queen's Printer: Codes of Practice

Plant and equipment safety procedures

UWA Plant and Equipment Safety Procedures 1 of 20 Plant and Equipment Safety Procedures Contents: Codes of Practice and Guidance Notes and all relevant laws pertinent to plant which include: identification, risk assessment and control of hazardous plant, provision of personal protective equipment (PPE), induction and training, standard operating procedures (SOP), emergency a meeting of experts to draw up a code of practice on safety and health in the use of machinery The meeting was held in Geneva from 29 November to 7 December 2011 Eight experts appointed following consultations with governments, eight following consultations with the Employers’ group and eight following consultations with the Workers’ group of the Governing Body participated in the Safety and health in the use of machinery Mobile crushing plant unintended movement of tracks Health and Safety Executive Safety alert Department Name: Field Operations Directorate Bulletin No: FOD 4 2011 Issue Date: 2 November 2011 Target Audience: Quarries, Mining, Construction, Demolition, Waste and Recycling and Others For the attention of owners and operators of mobile crushing plant Key Issues: There is Mobile crushing plant unintended movement of tracks

Guide to Food Safety Canadian Food Inspection Agency

The Guide to Food Safety is based upon the Recommended International Code of Practice General Principles of Food Hygiene adopted by the Codex Alimentarius Commission (Codex) in 2003 It is consistent with Codex's recommendations to enhance food safety by applying a systematic preventive approach The Guide to Food Safety is outcomebased It 106 Materials Plant Sites (Safety Manual), portions of the Construction Manual and Standard Specifications, and contractspecific standard special provisions dealing with safety In addition to the COSP, the resident engineer should be familiar with the provisions of the California Code of Regulations, Title 8 (CCR Title 8), “Industrial Relations,” applicable to the work in order to CODE OF SAFE PRACTICES California Department of Information on plant safety and injury prevention Plant includes machinery, equipment, appliances, implements and tools Plant: the basics Previous slide visual effect only Next slide visual effect only Plant: Safety basics Compliance code: Plant Plant health and safety guide Checklists and handbooks Previous slide visual effect only Next slide visual effect only Plant hazard Plant WorkSafe