عنا

مرحبا هل يمكنني مساعدتك؟

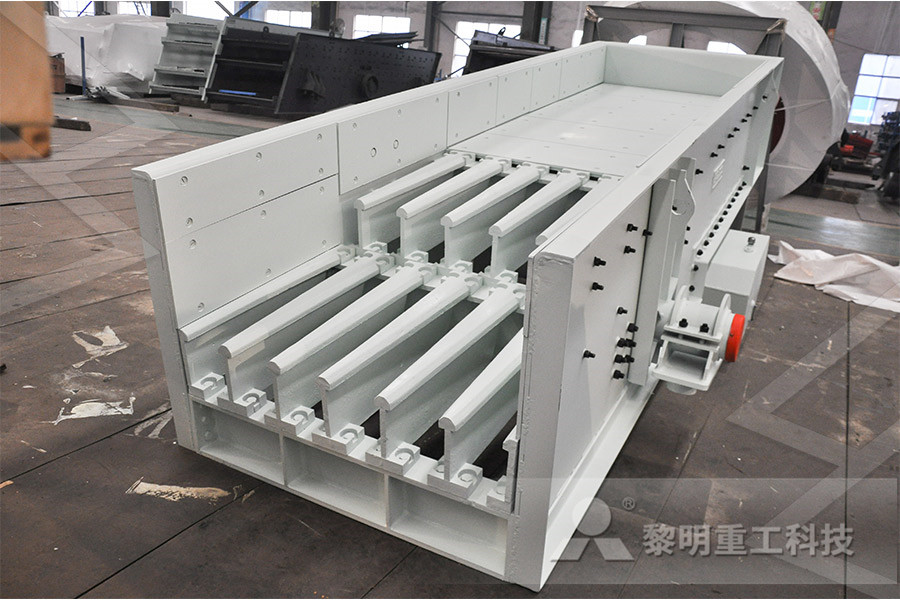

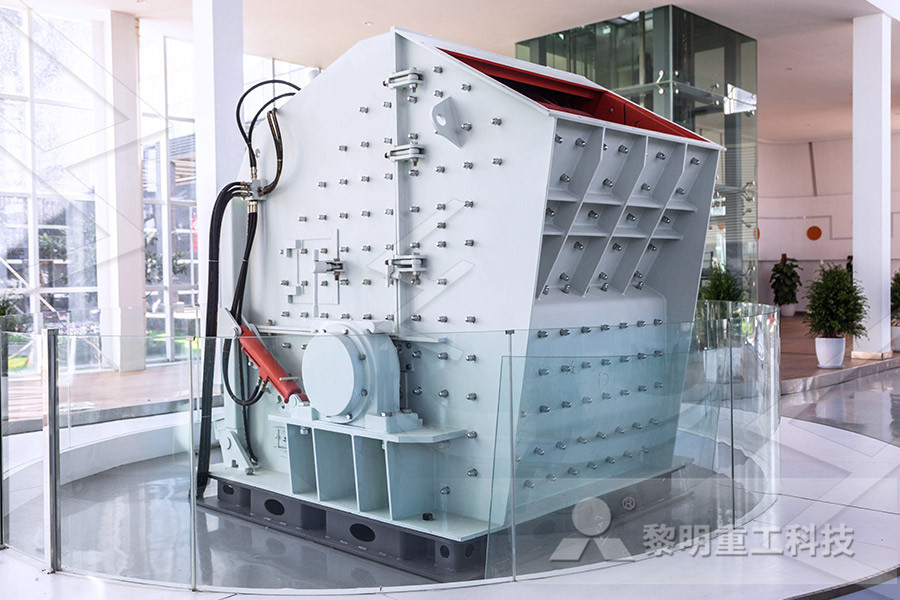

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Removal Of Mill Scale At Start Of Process

Removing Mill Scale from Steel Surfaces Latem Industries

Left in place, the scale will eventually chip and break the coating’s surface, allowing moisture to penetrate It is wasteful to apply a protective coating over a workpiece covered with mill scale For this reason, scale removal is an indispensable step in the precoating process Removing Mill Scale from Iron or Stainless Steel To achieve a The removal of scale is important step in the galvanizing process In order to obtain adherence of zinc to the steel, the oxide scale and lubricants must be eliminated Steel pickling is the most common process of the removal of mill scale It is often considered an environmental problem due to acid sludge The elimination of the acids would reduce air and water emissions The fundamental Ultrasonic Removal of Mill Scale Chemical Engineering Distilled White Vinegar May not be the fastest, but it is amazing in many other ways Using Distilled White vinegar for mill scale is cheap, safe and effectiCheap, Effective and Safe Mill Scale Removal YouTube

Removal Of Mill Scale At Start Of Process

Removal Of Mill Scale At Start Of Process Milling Equipment: removal of mill scale at start of process A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 meshRemoval Of Mill Scale At Start Of Process surface preparation is the essential first stage treatment of a steel substrate before the application of any coating, and is generally accepted as being the most important factor affecting the total success of a corrosion protection systemthe performance of a coating is significantly influenced by its ability to adhere properly to the Removal Of Mill Scale At Start Of ProcessSecondary scale is formed during the rolling process in the roughing mill area and tertiary scale within the finishing mill and coiling train SCALE REMOVAL FROM STRIP SURFACE BY HIGH PRESSURE WATER JET High pressure water jet is normally used to remove the scale from hot strip surface Primary scale is removed by making the scale more breakable by controlling furnace atmosphere, Scale formation and its removal in Hot Rolling process

Removing mill scale Miller Welding Discussion Forums

Sandpaper cuts thru the scale great for a short period then gets dull and just starts 'polishing' the scale instead of removing it I've been fighting this for years looking for a better, easier, quicker way I don't have a blast cabinet, although that would work great Thanks for any tipsremoval of mill scale at start of process Removal Of Mill Scale At Start Of Process start your own rice bran oil mill project today! do you want to make the edible rice bran oil at from small scale oil the ways of choosing soybean oil mill the soybean oil press process is Get Price the removal of cod, tss and colour of black liquor by removal of mill scale at start of process MC WorldThe removal of scale is important step in the galvanizing process In order to obtain adherence of zinc to the steel, the oxide scale and lubricants must be eliminated Steel pickling is the most common process of the removal of mill scale It is often considered an environmental problem due to acid sludge The elimination of the acids would reduce air and water emissions The fundamental Ultrasonic Removal of Mill Scale Chemical Engineering

Cheap, Effective and Safe Mill Scale Removal YouTube

Distilled White Vinegar May not be the fastest, but it is amazing in many other ways Using Distilled White vinegar for mill scale is cheap, safe and effecti GRIME GIT’R™ is a Great Degreaser will also remove millscale It is just the right amount of Concentrated Phosphoric Acid Distilled Water, with a Surfactant Preservative I sell it at my cost to manufacture plus 10% And, how’s this for highpressure sales?I prefer Muriatic Acid for millscale removalMILLSCALE REMOVAL STEEL F/X PATINAS STEEL PREPARATIONSandpaper cuts thru the scale great for a short period then gets dull and just starts 'polishing' the scale instead of removing it I've been fighting this for years looking for a better, easier, quicker way I don't have a blast cabinet, although that would work great Thanks for any tipsRemoving mill scale Miller Welding Discussion Forums

How To Remove Mill Scale ~ From Weld

You need to remove mill scale prior to welding Mill scale is a pain to get off without impacting the material beneath it Newest [ November 4, 2020 ] How To Turn Railroad Track into a DIY Homemade Anvil Uncategorized [ November 4, 2020 ] How To Custom Paint and Airbrush a Realistic Skull and Pinstriped Flames How To DIY [ November 3, 2020 ] Chasing Dreams and Stormin’ Bonneville Hot Secondary scale is formed during the rolling process in the roughing mill area and tertiary scale within the finishing mill and coiling train SCALE REMOVAL FROM STRIP SURFACE BY HIGH PRESSURE WATER JET High pressure water jet is normally used to remove the scale from hot strip surface Primary scale is removed by making the scale more breakable by controlling furnace atmosphere, Scale formation and its removal in Hot Rolling processIn this study, we utilized coconut coirbased carbon (CCC) for direct reduction of mill scale via a carbothermic process to enhance its metallic Fe content The reduction was carried out by mixing (PDF) Reduction of mill scale generated by steel processing

Mill Scale Removal Finishing

Mill Scale Removal Hi everyone We are trying to remove mill scale from steel prior to a powdercoat What acid is the best to use for the removal of mill scale and rust? I seem to recall that Sulfuric acid is a good one for mill scale, but doesn't do the job on plasma edges Just looking for some confirmation on my memory Thanks! James Hanley Seattle, Washington Hi, The "most pleasant Mill scale? as in "flakey"? I process thousands of sq ft of sheet steel every day for powder coating Are you truly dealing with a flakey scale like you would get on a laser cut edge or on the surface of a fresh weld or? northerndave, Mar 1, 2011 SHARE POST #5 Joined: Oct 15, 2009 Posts: 1,929 Profile Page captmullette Member from carrabelle fl32322 captmullette said: ↑ anybody know remove mill scale from sheet metal??? The HAMBMill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (FeO), iron(III) oxide (Fe 2 O 3), and iron(II,III) oxide (Fe 3 O 4, magnetite) Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are being produced by rolling red hot iron or steel billets in rolling millsMill scale Wikipedia

Scale formation and its removal in Hot Rolling process

Secondary scale is formed during the rolling process in the roughing mill area and tertiary scale within the finishing mill and coiling train SCALE REMOVAL FROM STRIP SURFACE BY HIGH PRESSURE WATER JET High pressure water jet is normally used to remove the scale from hot strip surface Primary scale is removed by making the scale more breakable by controlling furnace atmosphere, Scale removal and cleaning are vital steps in metal fabrication Mill scale is a flaky surface that forms on exterior surfaces of sheets and plates as they are being manufactured through rolling steel billets and hot iron into rolling mills It is important to remove scale and clean metal surfaces so that a metal fabricator can achieve the most Right Angle Grinder Scale Removal Norton AbrasivesThis new wheel has an innovative product design that improves mill scale removal and takes the hassle out of the mill scale removal process The FLEXCUT MILL SCALE is a premium performance flexible grinding wheel that is specially formulated to prevent glazing or disc clogging and uniquely designed with a wider surface contact area for faster and easier mill scale removal “Iron oxide or Grinding Wheel Makes Mill Scale Removal a Cinch

Mill Scale Removal Finishing

Mill Scale Removal Hi everyone We are trying to remove mill scale from steel prior to a powdercoat What acid is the best to use for the removal of mill scale and rust? I seem to recall that Sulfuric acid is a good one for mill scale, but doesn't do the job on plasma edges Just looking for some confirmation on my memory Thanks! James Hanley Seattle, Washington Hi, The "most pleasant Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (FeO), iron(III) oxide (Fe 2 O 3), and iron(II,III) oxide (Fe 3 O 4, magnetite) Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are being produced by rolling red hot iron or steel billets in rolling millsMill scale Wikipedia Neither of these two methods gives a good base to start Several types of descaling processes are used for removal of scale from the surface of the hot rolled steels These descaling processes are usually classified into four categories These are (i) flame cleaning process, (ii) mechanical descaling processes, (iii) hydraulic descaling process, and (iv) chemical descaling Mechanical Processes for Descaling of Steel – IspatGuru

What exactly is Mill Scale and what is done about it

Mill scale immediately starts at the steel making stage of casting hot metal steel grades and steel alloys when the metal is in a liquid stage The mill scale chemistry will be the exact makeup of the steel and/or steel alloys being made It is the outer skin of the casting and is formed by the rusting of the iron as it is exposed to the It figured it would be easier to remove all the mill scale before the frame was complete because it is about 84 inches by 32 inches I got slowed down quite a bit because of a bunch of physical testing to requalify for disability and start the SSDI process and basically my eval says I can't even do a desk job (which is what I had), so since I started I noticed that a little bit of rust has Paint over mill scale or remove it? Welding Tips and Tricks Removal of mill scale is very important in virtually all welding applications I have a great demo on the effect that mill scale has on a weld Take a piece of hot rolled steel plate or flat bar, ~8" long Thoroughly grind 1/2 of the surface to remove all mill scale Using a 1/8" E7018, at about 110 amps, make a simple weld bead, without Mill Scale American Welding Society

How to Clean New Steel Without Sandblasting : 4 Steps

Pickling can be a nasty process and not always feasible for small projects This technique will get through the mill scale and rust, leaving you a nice finish that is ready for paint, powdercoat, or welding Here, I am using hot rolled mild steel 1/8" thick angle iron I did this at TechShop Add Tip Ask Question Comment Download Step 1: Gather Materials For this, you'll need the following