عنا

مرحبا هل يمكنني مساعدتك؟

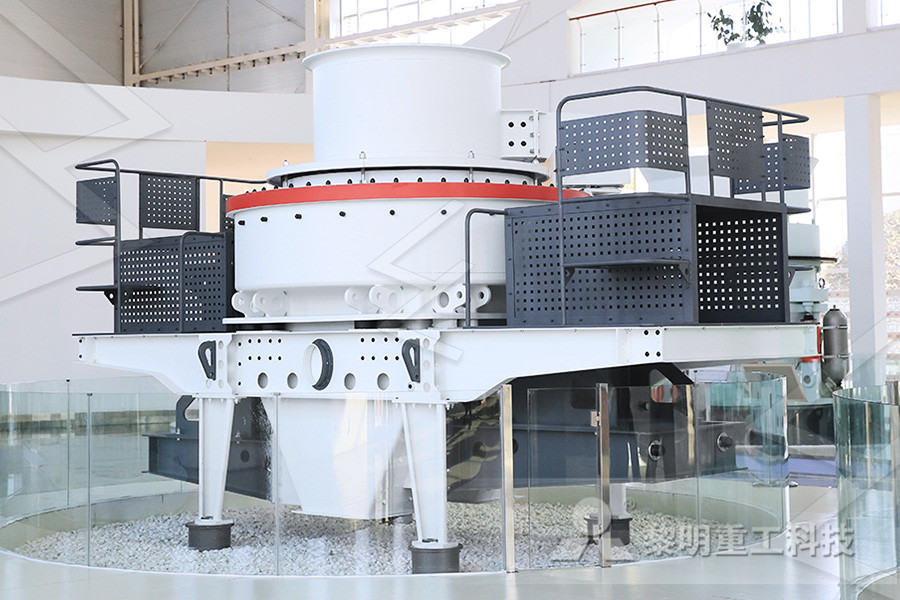

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

separation of pper by flotation

Coppermolybdenum ore beneficiation,flotation separation

In the coppersulfur separation operation, due to the large amount of lime and the fine grinding particle size, it has a greater impact on the corresponding flotation of molybdenite; in the actual copper separation operation, the copper recovery rate is only ≤50 % Classified slurry from the grinding circuit is dewatered in a flotation feed thickener from where feeds a three stage copper–lead–zinc sequential flotation circuit The copper flotation section produces a copper concentrate through two stages of flotation as shown in Fig 1 Flotation reagents are added through the conditioning tank, TKF2Flotation separation of copper sulphides from arsenic Flotation separation of copper and solder Flotation is commonly used to separate and recover minerals from gangue Here, flotation was used to separate copper from coppertin alloy Vibration mill was used in the fine crushing process of materialsNew insights into the mechanism of selective flotation of

Mining Industry Copper Sulfide Ore and Flotation Process

(7) Arsenic sulfide copper ore The ore has a high content of arsenic, which is mainly in the form of arsenopyrite Flotation process to solve the problem of copper and arsenic separation, reduce the arsenic content in the copper concentrate as much as possible 2 Copper Flotation And Gold Separation Summary is often a expert and renowned mining and construction machine manufacturer all over the world Depending on the high technologies and abundant expertise, has created the copper flotation and gold separation machine to suit the production desires Here is definitely the comprehensive data of You May Be Interested In Detailed Introduction Copper Flotation And Gold Separation Metallurgical ContentThe Problem with copperpyrite oresThe copper pyrite separation Process FlowsheetCrushing circuit of a copper pyrite oreCopper pyrite ore Grinding circuit Flotation process of CopperPyrite mineralsSampling The Problem with copperpyrite ores This flowsheet, is designed for the treatment of a copperiron sulfide ore containing appreciable values in gold The Copper and Pyrite Separation by Selective and Sequential

Copper Lead Concentrate Separation

The ways to obtain successful Separation of Copper and Lead into individual Concentrates, several process approaches can be examined; bulk copperlead flotation with a reverse flotation stage depressing copper, the same bulk flotation with a reverse flotation to depress lead and a sequential copperleadzinc flotation circuit as well as a simple cleaning of the bulk Cu/Pb The predominant configuration is sequential flotation, where copper bearing minerals are recovered to a saleable copper concentrate, followed by reactivation and flotation of the pyrite which is leached with cyanide to recover gold Both trains produce a copper concentrate with significant quantities of nonsulphide gangue mineralsSeparation efficiency improvement of a low grade copper Flotation is widely used to concentrate copper, lead, and zinc minerals, which commonly accompany one another in their ores Many complex ore mixtures formerly of little value have become major sources of certain metals by means of the flotation processFlotation ore dressing Britannica

(PDF) A Review of the Flotation of Copper Minerals

The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 05%TCu (open pit mines) and 12%TCu (underground mines) is of great commercial importanceMinerals Separation's initial flotation patents ended 1923, Froth flotation cells to concentrate copper and nickel sulfide minerals, Falconbridge, Ontario Froth flotation is a process for separating minerals from gangue by taking advantage of differences in their hydrophobicity Hydrophobicity differences between valuable minerals and waste gangue are increased through the use of Froth flotation Wikipedia3 Summary of the copper mineral flotation process (1) Copper minerals (such as chalcopyrite and covellite) that do not contain iron are similar in floatability Cyanide and lime have weaker inhibition on them, so a large amount of lime can be added to inhibit pyrite in the separation of copper and sulfur without seriously affecting the floatability of copper minerals (2) The copper minerals Mining Industry Copper Sulfide Ore and Flotation Process

Copper and Pyrite Separation by Selective and Sequential

Metallurgical ContentThe Problem with copperpyrite oresThe copper pyrite separation Process FlowsheetCrushing circuit of a copper pyrite oreCopper pyrite ore Grinding circuit Flotation process of CopperPyrite mineralsSampling The Problem with copperpyrite ores This flowsheet, is designed for the treatment of a copperiron sulfide ore containing appreciable values in gold The major portion Developing specific flotation collectors to improve the separation and enrichment of copper oxide minerals from their ores is still a challenging job In this article, a novel chelating collector, 5(2,4,4trimethylpentyl)4amino1,2,4triazolidine3thione (TMATT), was designed to separate and recover copper oxide minerals, and its flotation response to malachite, calcite, and quartz was Selective Flotation of Copper Oxide Minerals with A Novel This study aims to investigate the effects of operational variables on concentrate grade, recovery, separation efficiency, and kinetic parameters of the copper flotation process For this purpose, the effects of the pulp solids content, collector and frother dosage, and preparation and concentrate collection time were studied using a Taguchi experimental bined Effect of Operating Parameters on Separation

Flotation ore dressing Britannica

Flotation is widely used to concentrate copper, lead, and zinc minerals, which commonly accompany one another in their ores Many complex ore mixtures formerly of little value have become major sources of certain metals by means of the flotation process This article was most recently revised and updated by Chelsey ParrottSheffer, Research Editor Learn More in these related Britannica Froth flotation is the use of the physical and chemical properties of the surface of the ore, the use of chemical separation of useful ore In the process of froth flotation, useful minerals are separated by floating them in the foams, and the way of keeping gangue minerals in the pulp is called positive flotation, while the way of floating gangue minerals in the foam is called reverse flotation>Mineral Flotation, Flotation Separation, Forth Flotation Copper extraction refers to the methods used to obtain copper from its oresThe conversion of copper consists of a series of physical and electrochemical processes Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors As in all mining operations, the ore must usually be beneficiated (concentrated)Copper extraction Wikipedia

Copper Sulphide Ore Reagents For Copper Flotation

Copper lead zinc flotation flowsheetseparation by flotation of copper lead zinc sulp apr 23 2018 leadzinc ores c bulk flotation of copperleadzinc minerals followed by a selective separation of sulphide minerals can be achieved using a variety of collec used nontoxic reagents such as zinc sulphate sodium meta bisulphite caustic Live Chat ; Flotation Of Nickel The flotation recovery of ni, cu Metallurgical ContentFroth Flotation HandbookFROTH FLOTATIONBubble Contact Angle Froth FlotationHow Flotation Chemicals are UsedFunctions of Flotation ReagentsClassification of Flotation ReagentsFlotation Processing Costs The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground) minerals/metals and making/playing on making them Froth Flotation ProcessProblem: A copper ore initially contains 209% Cu After carrying out a froth flotation separation, the products are as shown in Table 1 Using this data, calculate: (a) Ratio of concentration (b) % Metal Recovery (c) % Metal Loss (d) % Weight Recovery, or % Yield (e) Enrichment Ratio Table 1: Grade/recovery performance of a hypothetical copper ore flotation process Product % Weight % Cu 1 Froth Flotation – Fundamental Principles

Flotation separation Machine for Copper indiasource

Flotation separation Machine for Copper Posted: July 9, 2012 Author: indiasource Filed under: india mining source Leave a comment Overview of Flotation Split up Technological Process Flotation separation is frequently defined as generic words of ore pulp flowing via every operation around flotation separation mechanisms for ores Various processes are generally applied to the (2020) The effect of degree of liberation on copper recovery from copperpyrite ore by flotation Separation Science and Technology: Vol 55, No 17, pp 32603273The effect of degree of liberation on copper recovery from Nevertheless, the similar flotation properties and surface chemistry of copper sulfides and copper arsenic phases result in the limitations of the separation of arsenic in the slag flotation Flotation separation of copper sulphides from arsenic

Mineral Flotation, Flotation Separation, Forth Flotation

Froth flotation is the use of the physical and chemical properties of the surface of the ore, the use of chemical separation of useful ore In the process of froth flotation, useful minerals are separated by floating them in the foams, and the way of keeping gangue minerals in the pulp is called positive flotation, while the way of floating gangue minerals in the foam is called reverse flotation>The flotation separation of molybdenite from copper sulfide minerals (mostly chalcopyrite) typically relies on the use of toxic inorganic depressants such as cyanides and sodium sulfide/hydrosulfide(PDF) Selective separation of coppermolybdenum sulfides 155 Bulk CopperLeadZinc Flotation Method and Separation of Copper, Lead and Zinc from Bulk Concentrate 388 156 Upgrading of Lead Concentrate from the CopperLead Separation Tailing 389 1561 Direct flotation of impurities from the copperlead separation tailing 390 1562 Lead flotation from the copperlead separation tailing 391 157 Reagent Practice in Operating Handbook of Flotation Reagents MESA

Froth Flotation Process

Metallurgical ContentFroth Flotation HandbookFROTH FLOTATIONBubble Contact Angle Froth FlotationHow Flotation Chemicals are UsedFunctions of Flotation ReagentsClassification of Flotation ReagentsFlotation Processing Costs The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground) minerals/metals and making/playing on making them A faster floating copper porphyry flotation test, however, may finish in five minutes and a first concentrate may need to be collected after 20 seconds Depending on one’s circumstances, some deviation may be required from the recommended test conditions (eg use of high per cent solids to obtain sufficient concentrate samples for assay, samples left to sit for long periods) Tests should be Laboratory Flotation Testing – An Essential Tool for Ore Separation Of Gold 2Csilverand Copper By Flotation Separation of gold silver and copper by flotation separation of gold silver and copper by flotation meeting an ever increasing demand for copper requires a partner proven not just on the drawing board, but in the real world, in designing, delivering and maintaining chat online silver fact sheets mines atlas most of australias silver is Separation Of Gold Silver And Copper By Flotation