عنا

مرحبا هل يمكنني مساعدتك؟

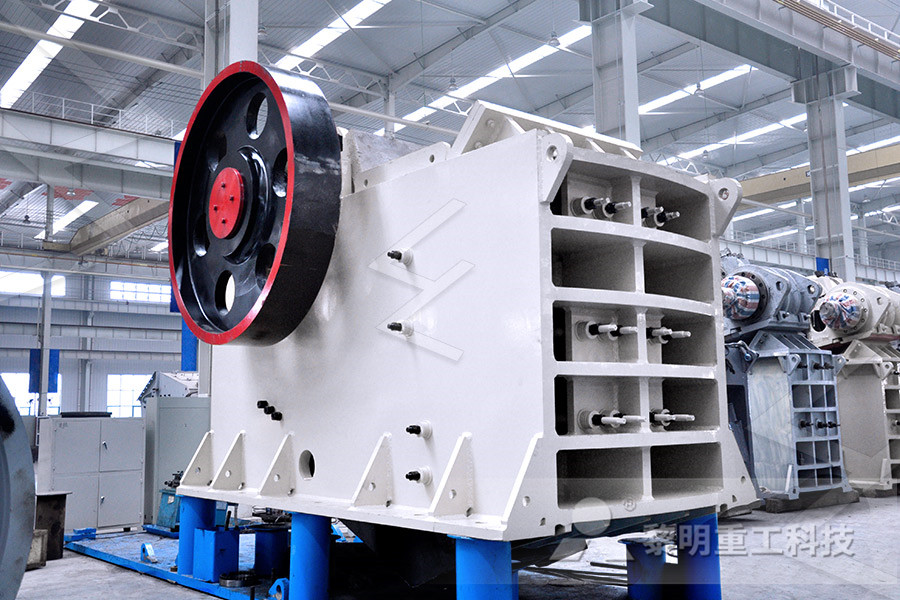

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding abrasive material

Different Approaches to Grinding Abrasive Materials

Fine Grinding Fine grinding abrasive materials is typically needed to create particle sizes in the minus 50 mesh range (297 microns) down to about 95% minus 325 mesh (45 microns) Some of these sizes are typically referred to as talc, flour, pulverized, or ballmill fine grades Abrasive material and hardness of grinding wheel are two important factors affecting the grinding efficiency and quality In this study, two kinds of abrasive grains (ie, zirconium corundum (ZA) and brown fused alumina (BA)) were used to produce eight grinding wheels, among which five with different contents of abrasive grains and four with different hardness levels Rail Effects of abrasive material and hardness of grinding Both silicon carbide and aluminum oxide abrasives are very hard and brittle, and as a result they tend to form sharp edges These edges help the abrasive to penetrate the work material and reduce the amount of heat generated during the abrasion This type of Abrasives How do abrasives work? Materials, Grinding

GRINDING AND OTHER ABRASIVE PROCESSES

•In addition to abrasive grains and bond material, grinding wheels contain air gaps or pores •Volumetric proportions of grains, bond material, and pores can be expressed as: P g P b P p 10 ©2002 John Wiley Sons, Inc M P Groover, “Fundamentals of Modern Manufacturing 2/e” Figure 251 Typical structure of a grinding wheel ©2002 John Wiley Sons, Inc M P Groover For example, you could grind for 10 minutes with each product, and measure how much material was removed and how much of the abrasive products were lost; this is often measured by weight Alternatively, you could run each product to the end of its life, while measuring how much material it removed, and how long it lasted Finally, you could remove a set amount of material while measuring the time Choosing the Right Abrasive Product for Welding and Metal The particular abrasive used in the cutting and grinding wheels is chosen based on the way it will interact with the work material Each abrasive type is unique with distinct properties for hardness, strength, fracture toughness and resistance to impact The good abrasive is Several Common Types of Abrasives Used in Grinding wheels

Grinding Stones McMasterCarr

A large grinding surface, combined with a thick layer of rough abrasive removes more material than other wheels They are also known as Type 11 wheels, flaredcup wheels, snagging wheels, and cup stones General Purpose Grinding Wheels for Angle Grinders— Use on MetalsAbrasive Material, Cut Off Wheel, Grinding Wheel Manufacturer in China Established in 2004, SANDE Group is a professional abrasive material and grinding tool manufacturer integrating scientific research, manufacture and marketing Our grinding materials are widely applied in the metallographic analysis and the grinding and polishing of limousine cars, optical instruments, electronic parts Abrasive Material, Cut Off Wheel, Grinding Wheel The grinding abrasives commonly used in materials preparation are silicon carbide (SiC), aluminum oxide (Al2O3), emery (Al2O3 Fe3O4), composite ceramics and diamond Emery paper is rarely used today in materials preparation due to its low cutting efficiency SiC is more readily available as waterproof paper than aluminum oxide These abrasives are bonded to paper, polymeric or cloth Grinding and Polishing Guide

Effects of abrasive material and hardness of grinding

Abrasive material and hardness of grinding wheel are two important factors affecting the grinding efficiency and quality In this study, two kinds of abrasive grains (ie, zirconium corundum (ZA) and brown fused alumina (BA)) were used to produce eight grinding wheels, among which five with different contents of abrasive grains and four with different hardness levelsApplications for abrasives generally fall in the following categories: 1) cleaning of surfaces and the coarse removal of excess material, such as rough offhand grinding in foundries; 2) shaping, as in form grinding and tool sharpening; 3) sizing, primarily in precision grinding; and 4) separating, as in cutoff or slicing operationsAbrasives How do abrasives work? Materials, Grinding Abrasive Technology is wellequipped to deliver innovative solutions with PBS® braze, electroplated, resin bond and metal bond products We offer multiple options for working with difficult materials and applications, including small geometries when something is especially difficult to cut We provide material removal for whatever you're working with—steels, tool steels, stainless steels Grinding Abrasive Technology

Bond Selection for Production Grinding Norton Abrasives

First, let’s look at the makeup of a typical grinding wheel (Figure 1) Abrasive grains are generally considered to be the primary component and can be traditional oxide or other ceramic material, diamond, or cBN (cubic boron nitride) A bonding medium holds the abrasive grains within the wheel structure and provides bulk strength Free space, or porosity, is intentionally included within •In addition to abrasive grains and bond material, grinding wheels contain air gaps or pores •Volumetric proportions of grains, bond material, and pores can be expressed as: P g P b P p 10 ©2002 John Wiley Sons, Inc M P Groover, “Fundamentals of Modern Manufacturing 2/e” Figure 251 Typical structure of a grinding wheel ©2002 John Wiley Sons, Inc M P Groover GRINDING AND OTHER ABRASIVE PROCESSES grinding wheels may be used for light stock removal and finishing in one operation (24 grit for blending; 36 grit for finishing) Cotton fiber combined with abrasive and flexible bonding material is especially good for bronze, aluminum and thin sheet steel; Blending welds; Deburring; Seethrough fiber discs (60 to 120 grit for light deburring)Choosing the Right Abrasive Product for Welding and Metal

How grinding wheel is made material, history, used

Abrasive grains constitute the central component of any grinding wheel, and the hardness and friability of the grinding materials will significantly affect the behavior of a given wheel Hardness is measured in terms of a relative scale developed in 1812 by a German mineralogist named Friedrich Mohs On this scale, extremely soft talc and gypsum represent hardnesses of one and two, and Abrasive definition, any material or substance used for grinding, polishing, etc, as emery, pumice, or sandpaper See moreAbrasive Definition of Abrasive at DictionaryThe whetstone comprises abrasive grains, a bonding material, and pores The abrasive grains play the role of a cutting edge, the bonding material fixes and supports the grains, and the pores act as a chip pocket to help discharge of cutting chips In whetstones where the bonding material is a resinoid bond or metal bond, there are not normally any pores The process whereby a grinding wheel Abrasive Grain an overview ScienceDirect Topics

GRINDING AND OTHER ABRASIVE PROCESSES

•In addition to abrasive grains and bond material, grinding wheels contain air gaps or pores •Volumetric proportions of grains, bond material, and pores can be expressed as: P g P b P p 10 ©2002 John Wiley Sons, Inc M P Groover, “Fundamentals of Modern Manufacturing 2/e” Figure 251 Typical structure of a grinding wheel ©2002 John Wiley Sons, Inc M P Groover Floor Grinding Bonded Abrasives Floor Grinding Blocks View larger Filter Abrasive Material Bonded Abrasives (5) Activity / Use Grinding (4) Equipment Compatibility Right Angle Grinders (4) Surface Type Concrete (4) Option Abrasive Material Activity / Use Equipment Compatibility Surface Type Unit Purchase; Blocks, Flr Grinding 2x2x4 8 42630802 Bonded Abrasives Grinding Right Virginia Abrasives Floor Grinding Bonded Abrasives Grinding employs an abrasive product, usually a rotating wheel brought into controlled contact with a work surface The grinding wheel is composed of abrasive grains held together in a binder These abrasive grains act as cutting tools, removing tiny chips of material from the work As these abrasive grains wear and become dull, the added resistance leads to fracture of the grains or weakening Basics of Grinding Manufacturing

Abrasive Material, Cut Off Wheel, Grinding Wheel

Abrasive Material, Cut Off Wheel, Grinding Wheel Manufacturer in China Established in 2004, SANDE Group is a professional abrasive material and grinding tool manufacturer integrating scientific research, manufacture and marketing Our grinding materials are widely applied in the metallographic analysis and the grinding and polishing of limousine cars, optical instruments, electronic parts GRINDING Abrasive process Metal is removed with the help of ROTATING GRINDING WHEEL Wheels are made of fine grains of abrasive materials held together by a bonding material called a BOND Types of operations performed in cylindrical grinding 1 TRAVERSE GRINDING 2 PLUNGE GRINDING Conventional grinding machines can be broadly classified as: (a) Surface grinding machine (b) TYPES OF GRINDING WHEELSAbrasive materials Tools made by “ANDRE” contain modern, hard abrasive materials Aluminum oxide (synthetic corundum) αAl2O3 Aluminum oxide in different variations is the most frequently used abrasive material It is melted from bauxite or aluminium oxide at temp over 2000ºC in electric furnaces 95A Normal aluminium oxide (brown)Abrasive materials ANDRE ABRASIVE ARTICLES

Grinding Stones McMasterCarr

RubberCushioned Abrasive Grinding Discs without Shank for Metals The abrasive grains in these discs are blended with rubber, which cushions during grinding to produce a smoother surface texture than other discs with similar grits Discs attach to your grinder with a shank Grinding Bits for Stainless Steel Bits stay cool during grinding so they won’t mar or discolor stainless steel Hex Abrasive definition, any material or substance used for grinding, polishing, etc, as emery, pumice, or sandpaper See moreAbrasive Definition of Abrasive at Dictionary244 Which one of the following is not one of the five basic parameters of a grinding wheel: (a) abrasive material, (b) bonding material, (c) grain hardness, (d) grain size, (e) wheel grade, or (f) wheel structure? Answer (c) 245 Friability refers to the capacity of the abrasive material to retain its sharpness during the grinding operation: (a) true or (b) false? Answer (b) Friability Chapter 24 GRINDING AND OTHER ABRASIVE PROCESSES